It Pay’s To Read The manual

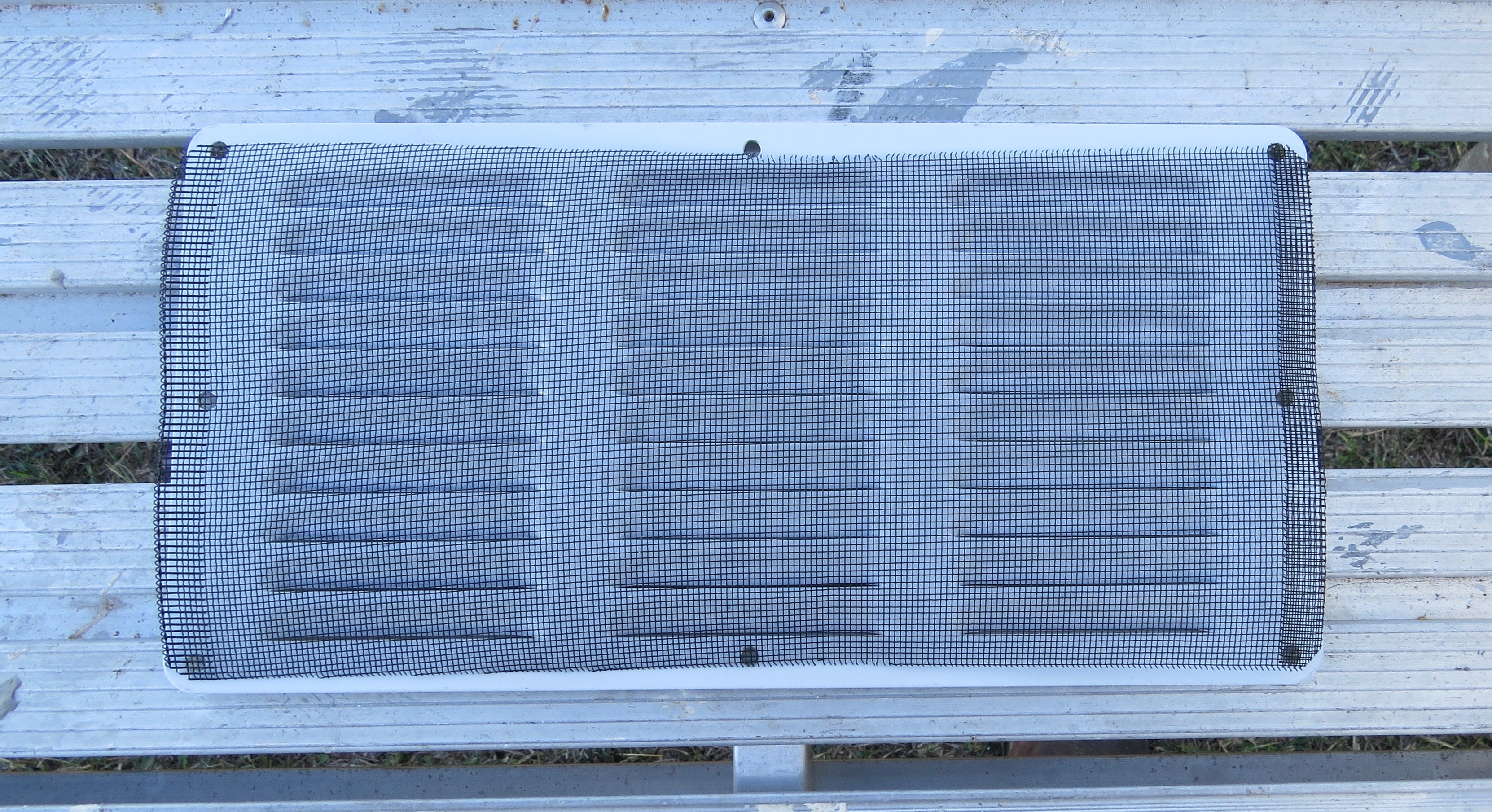

Being a typical man I put some vents in for the fridge, but now after reading the installation manual I have found out that the vent’s are way to small. So off to the caravan shop to oder the right size vent’s as well as an extension for the flu so the hot air go’s straight out side. The post about putting the small vent’s Prep work for the new fridge. Not what to do !!!

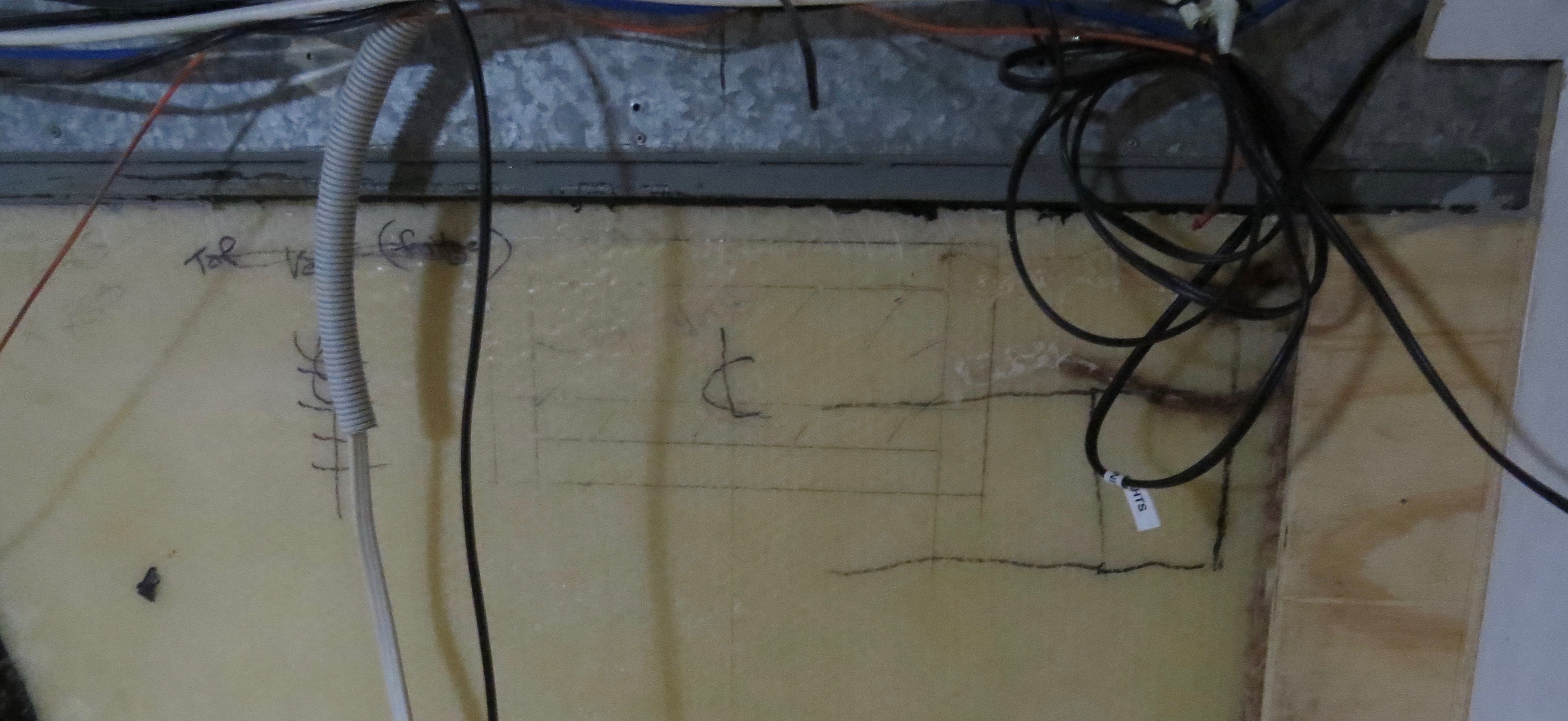

Time to make a mess & rip out the vent’s

So now is the time to start pulling the vents out, the only problem is I fitted them to well. This is not going to be fun at all, but lesson learnt and I’ll read every manual from now on.

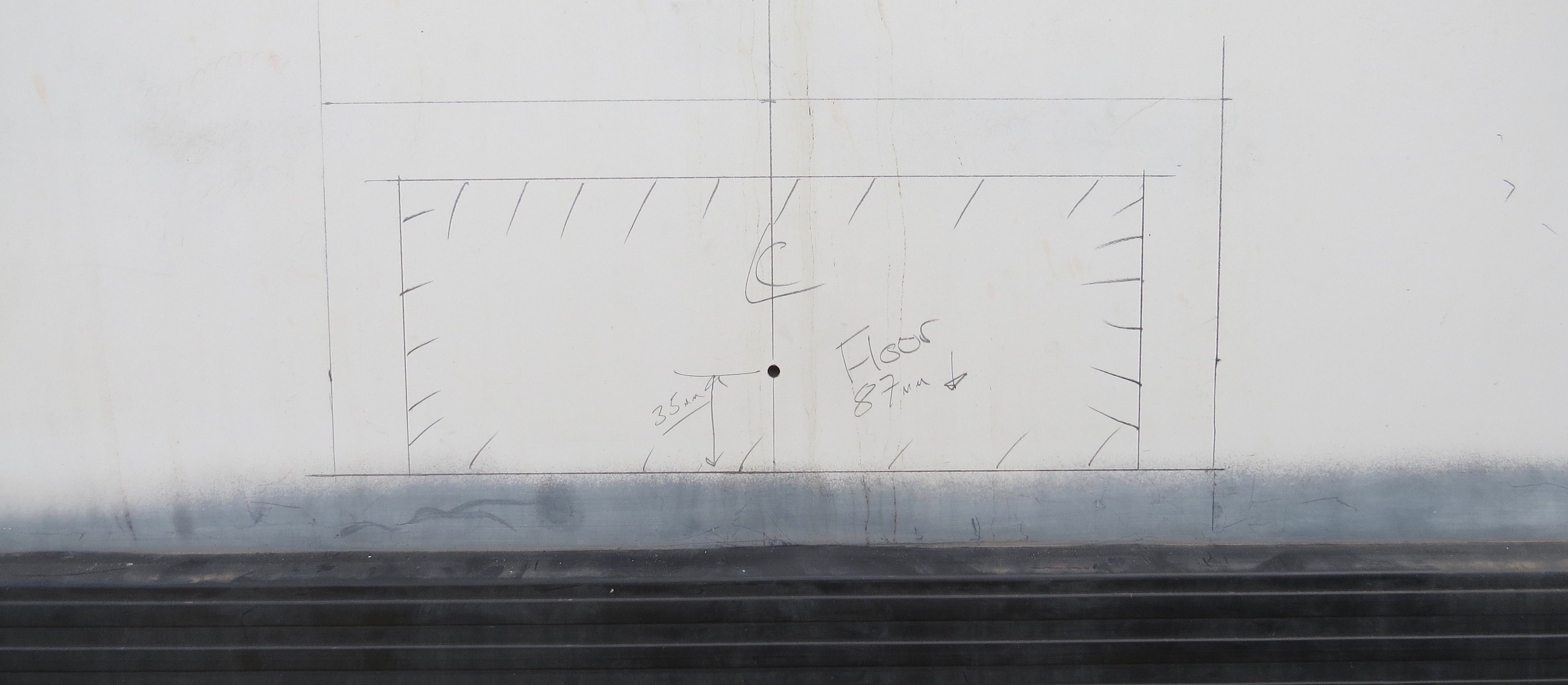

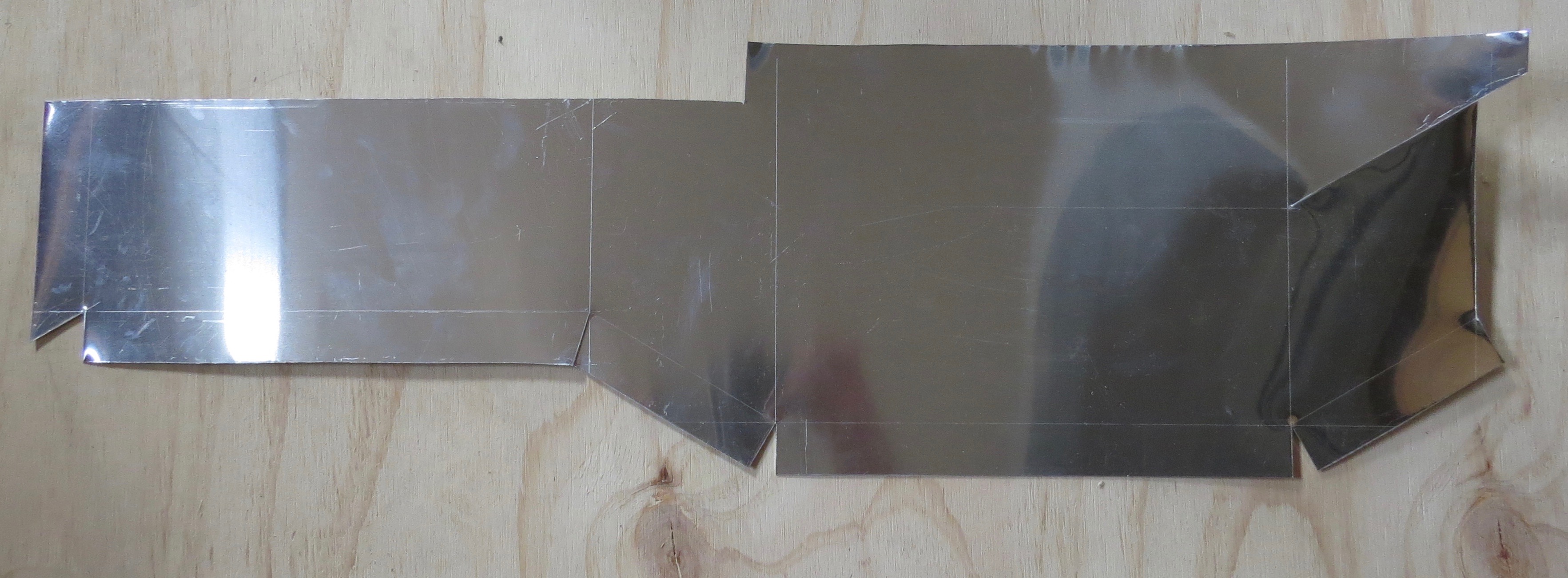

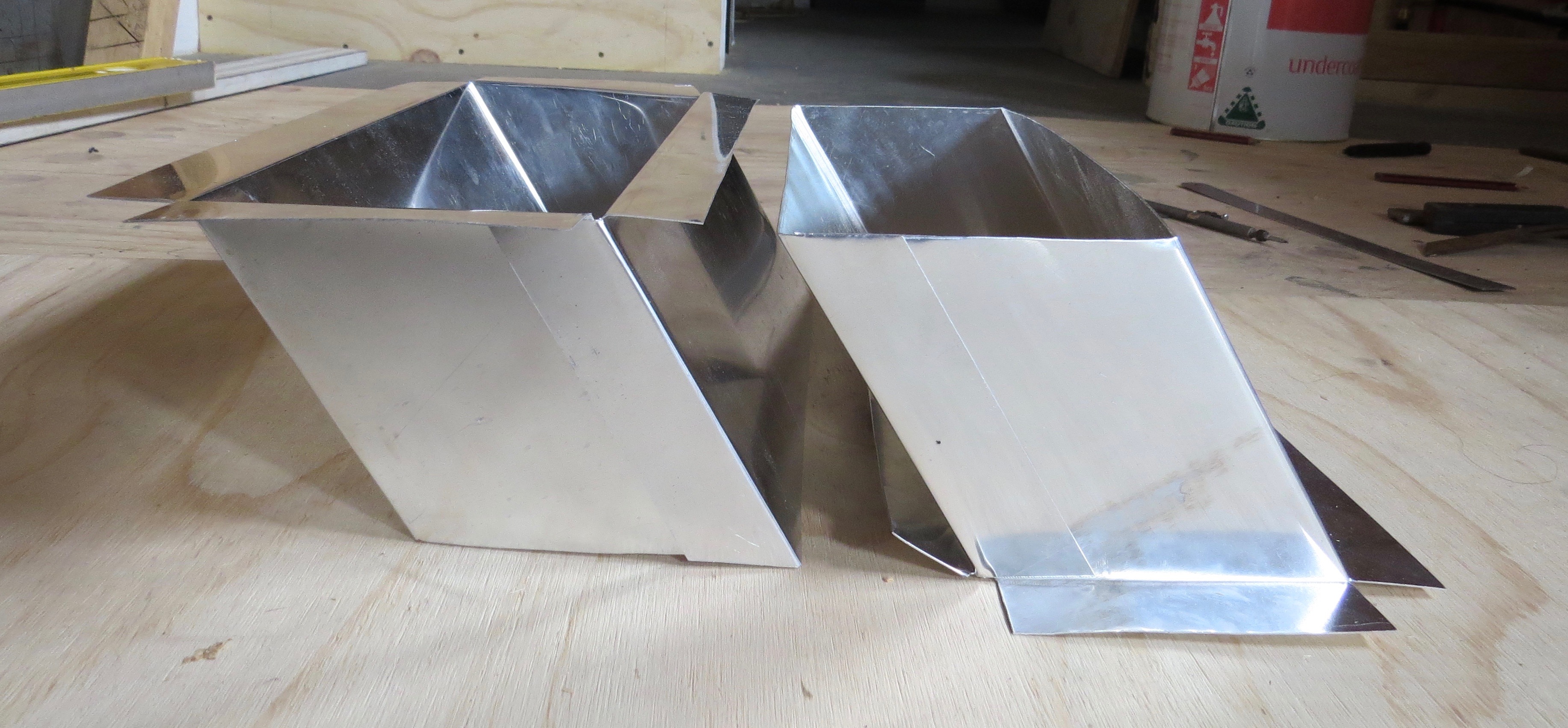

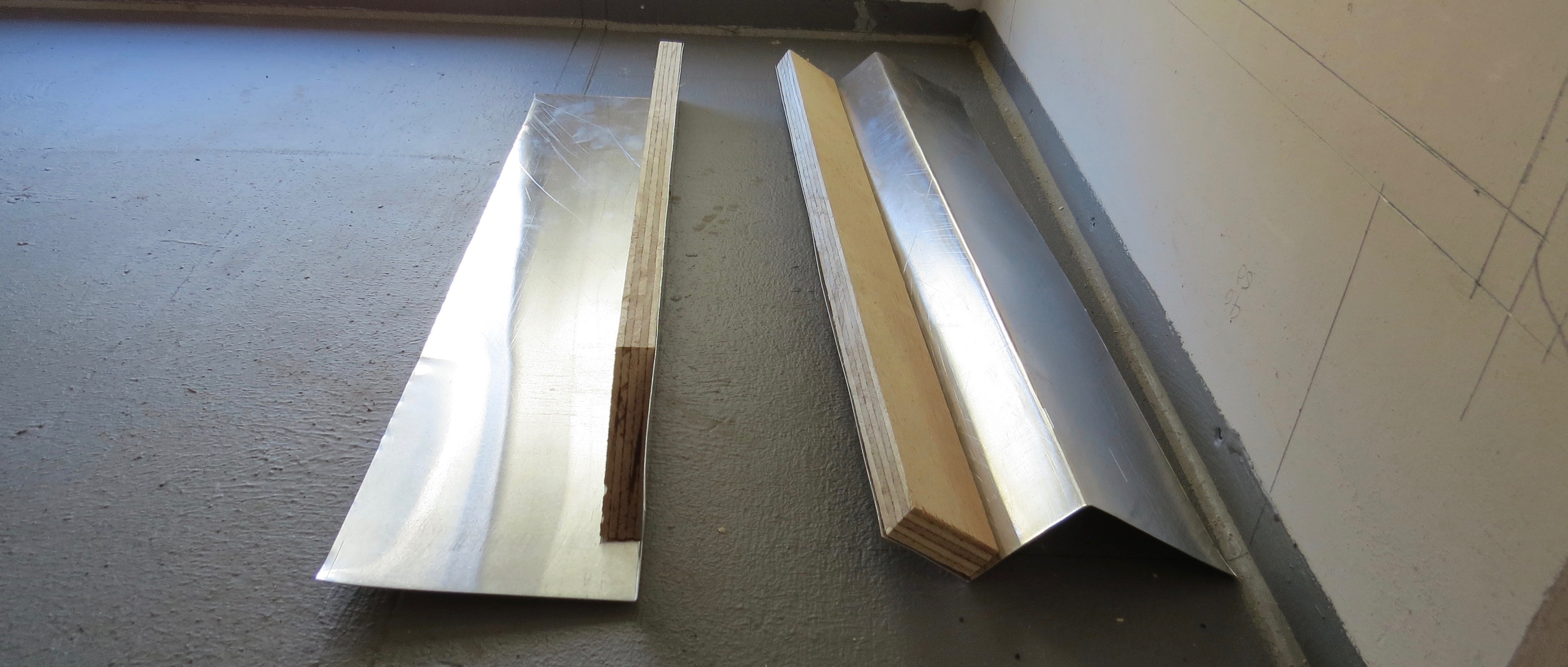

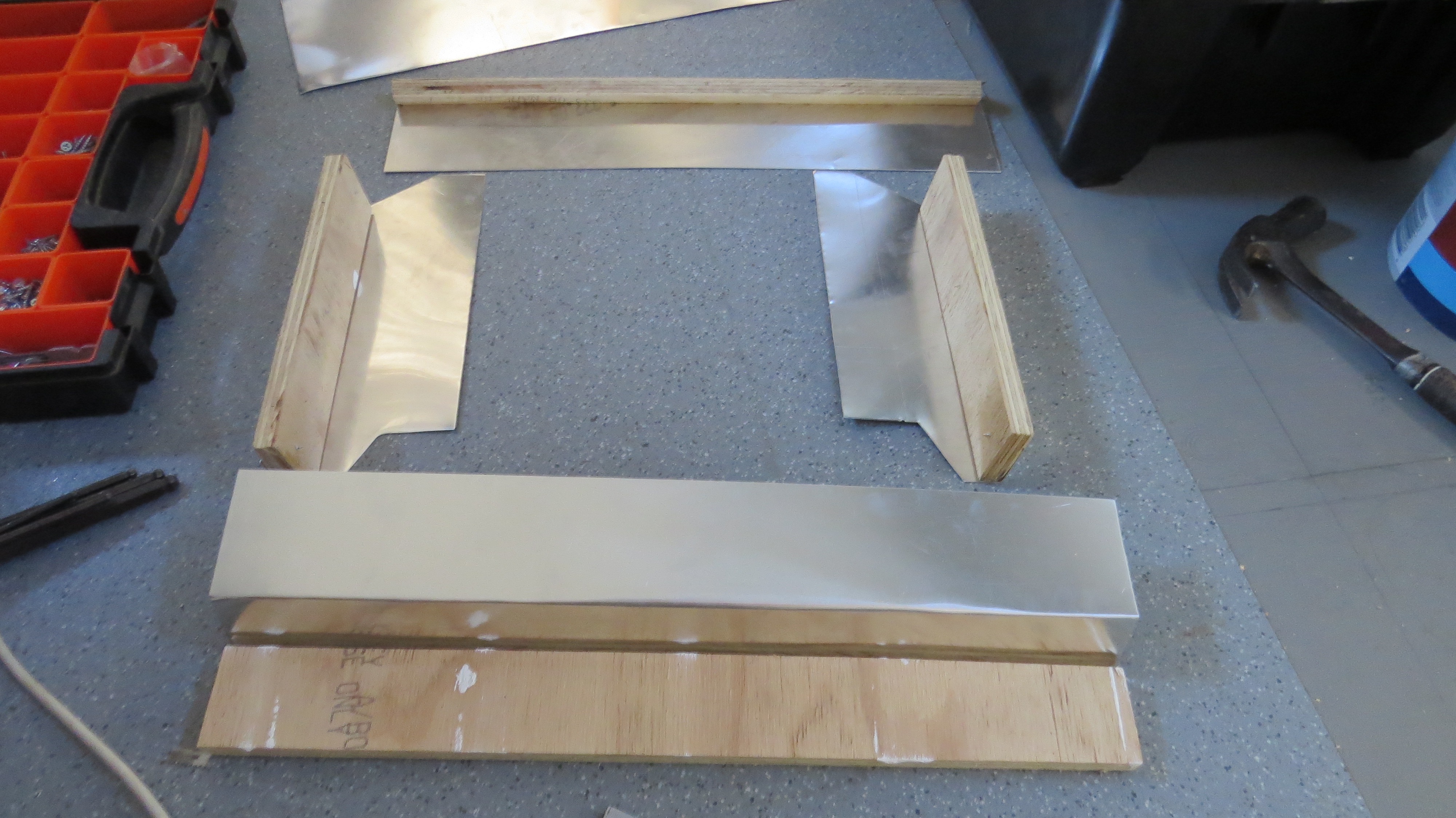

Now that I’ve cut the bottom hole to size, next will be to bend up some sheet metal to fit in the gap so it will be waterproof again. This will be one pice at a time not like the first time when I made up the ducting in one pice.

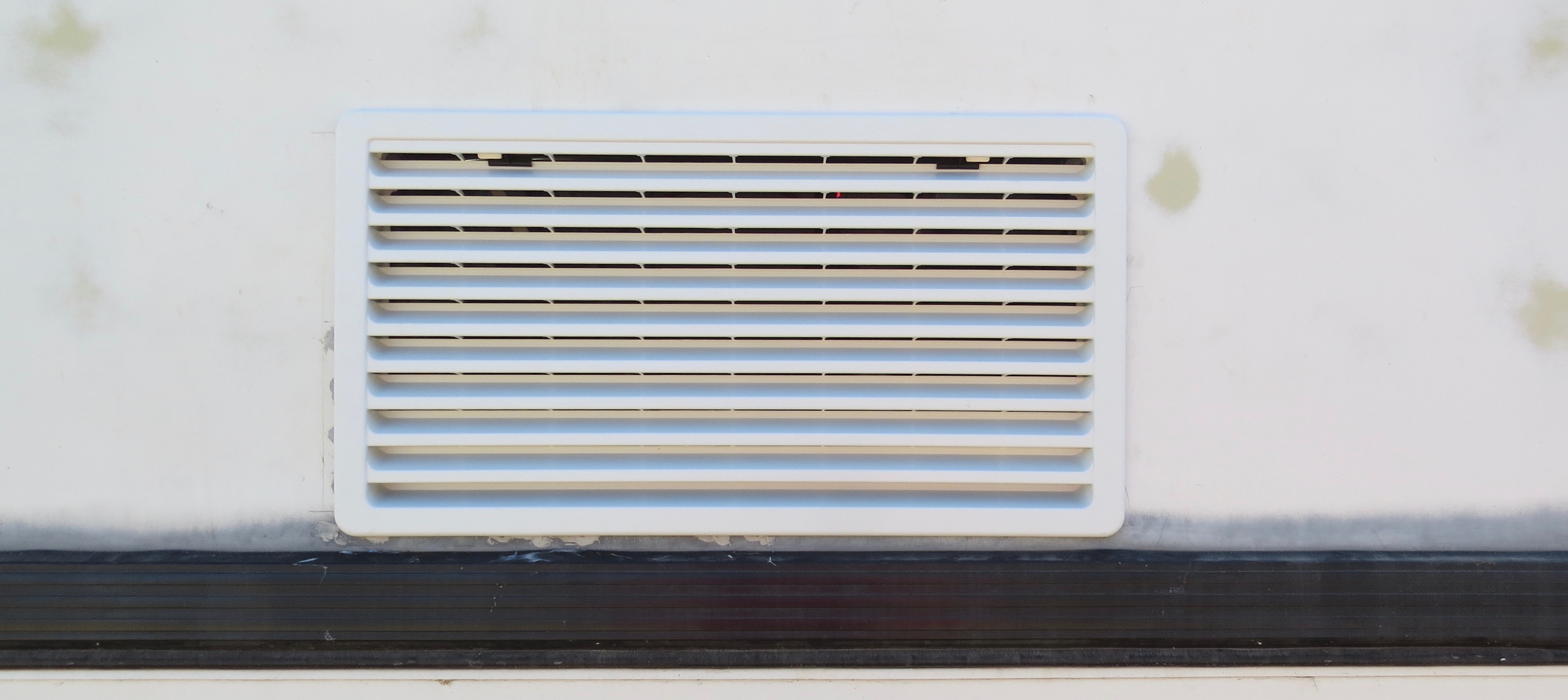

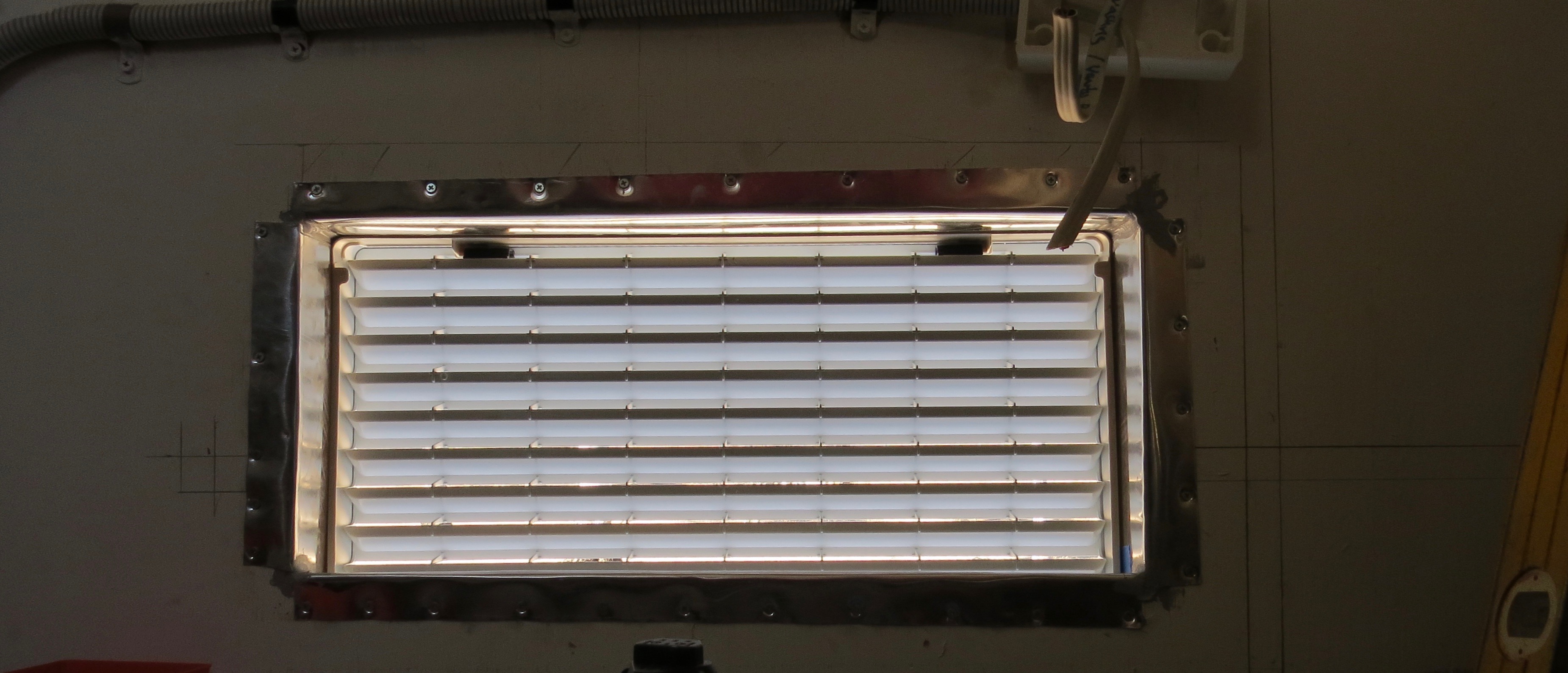

The right size vents now

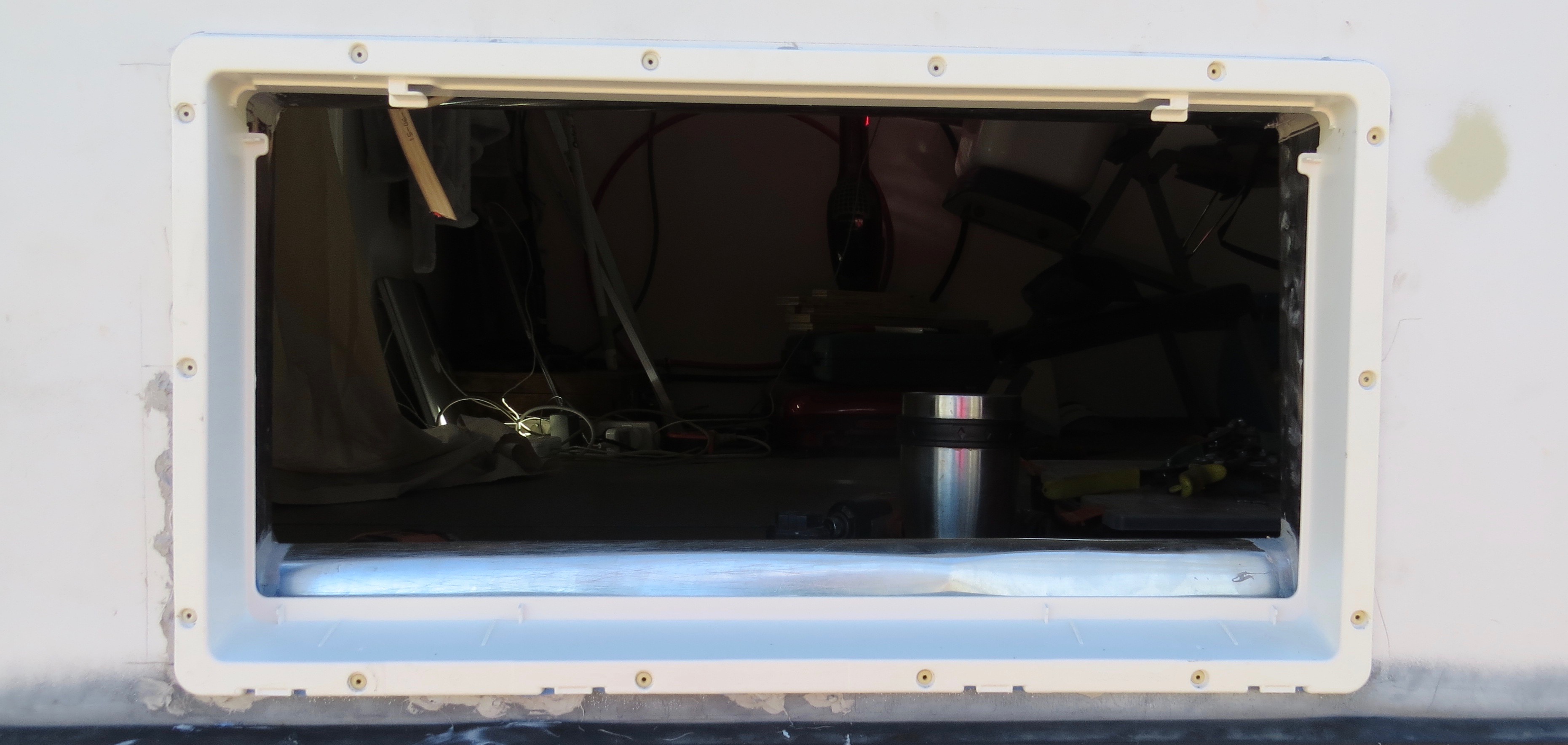

After fixing the bottom and top vent holes, now it’s only a matter of fitting the new right size vent covers. Now this was the best part as I know I’ve got it right this time!!

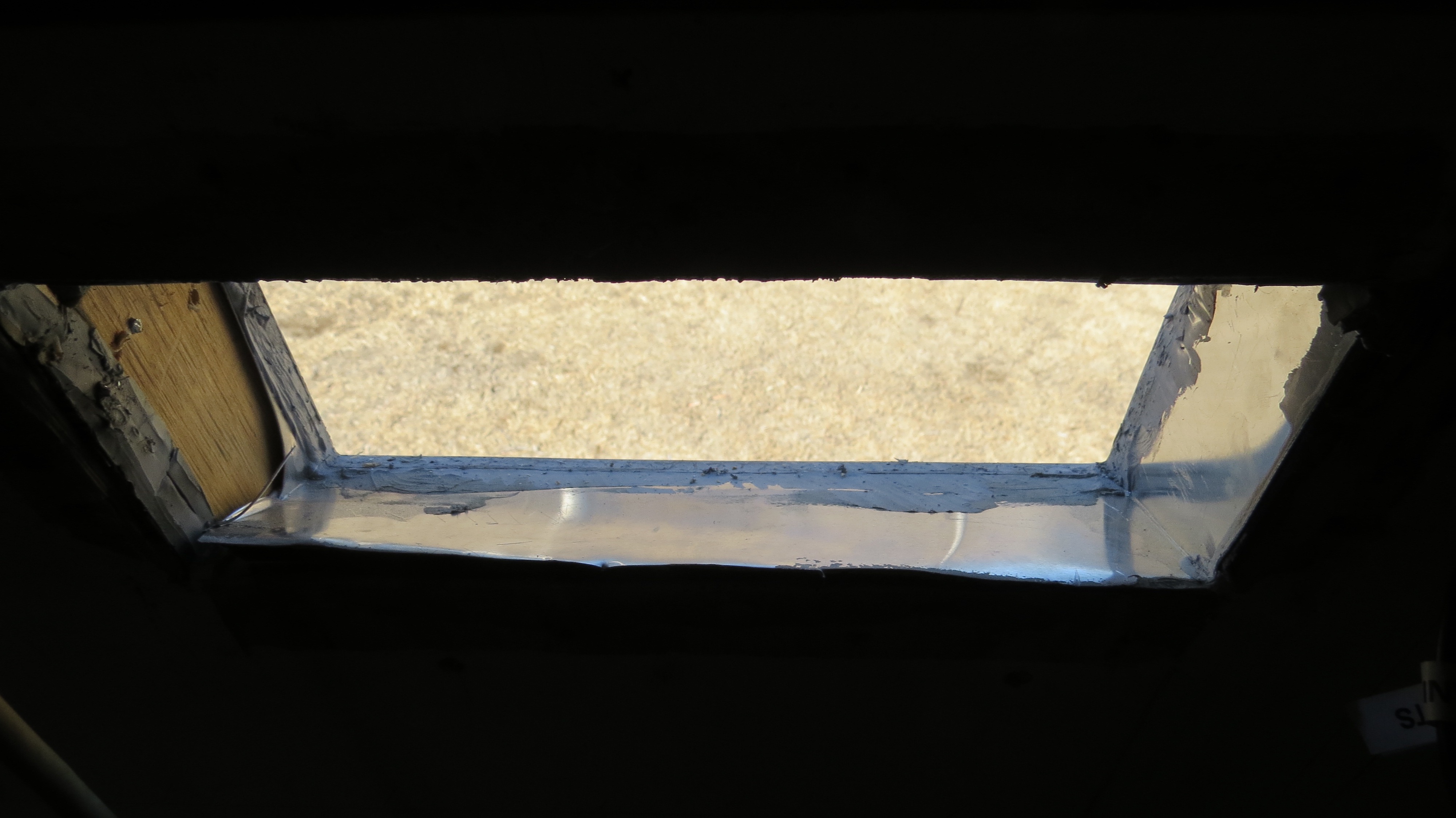

Now for the top vent

F!#k this is not fun as the top vent is even a bigger pain to get out, as I had timber all the way around the vent hole.

Now that job is finish for the last time I think I need a drink. But lesson learnt I will always read the installation manual first before starting another job.