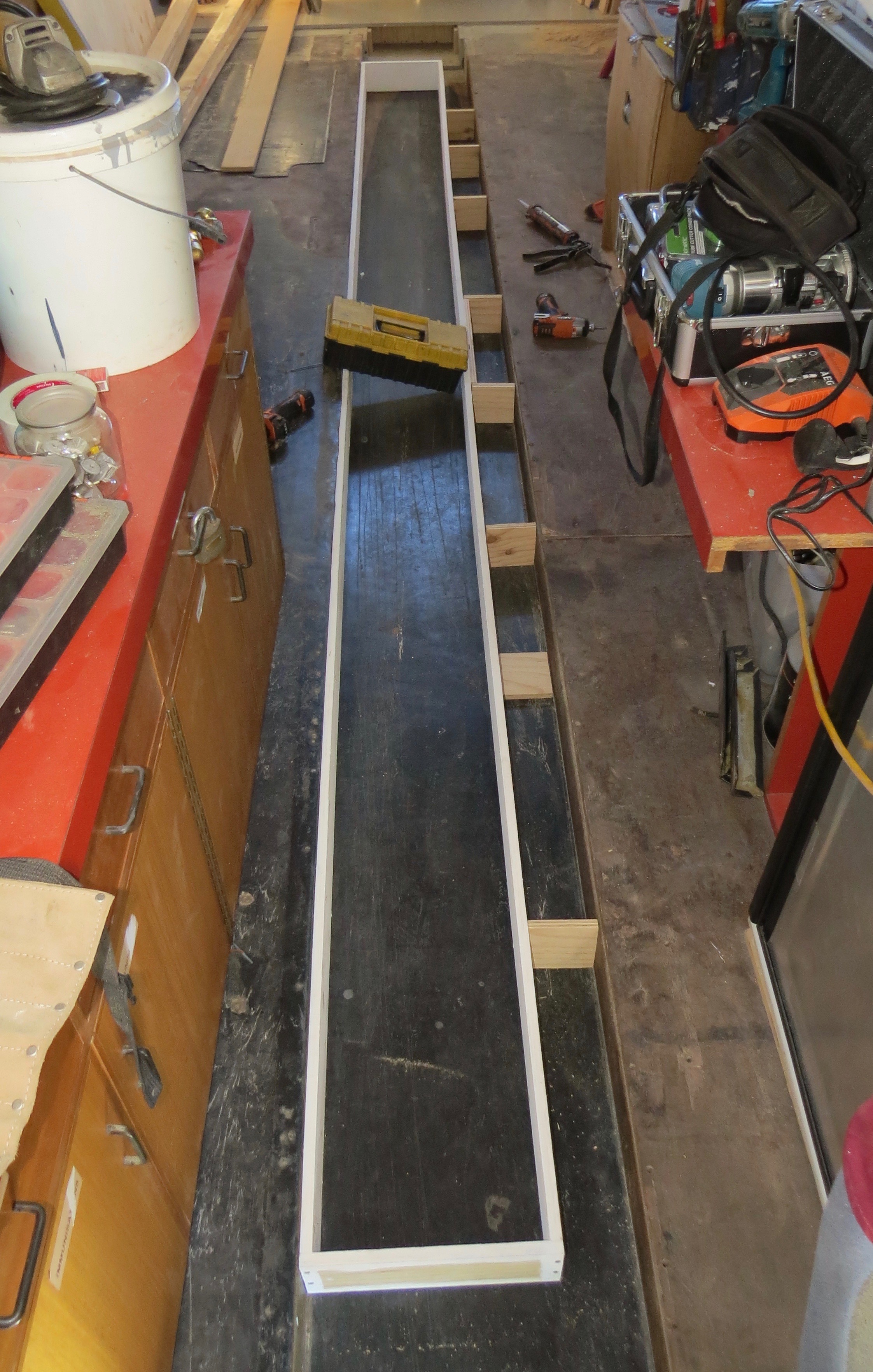

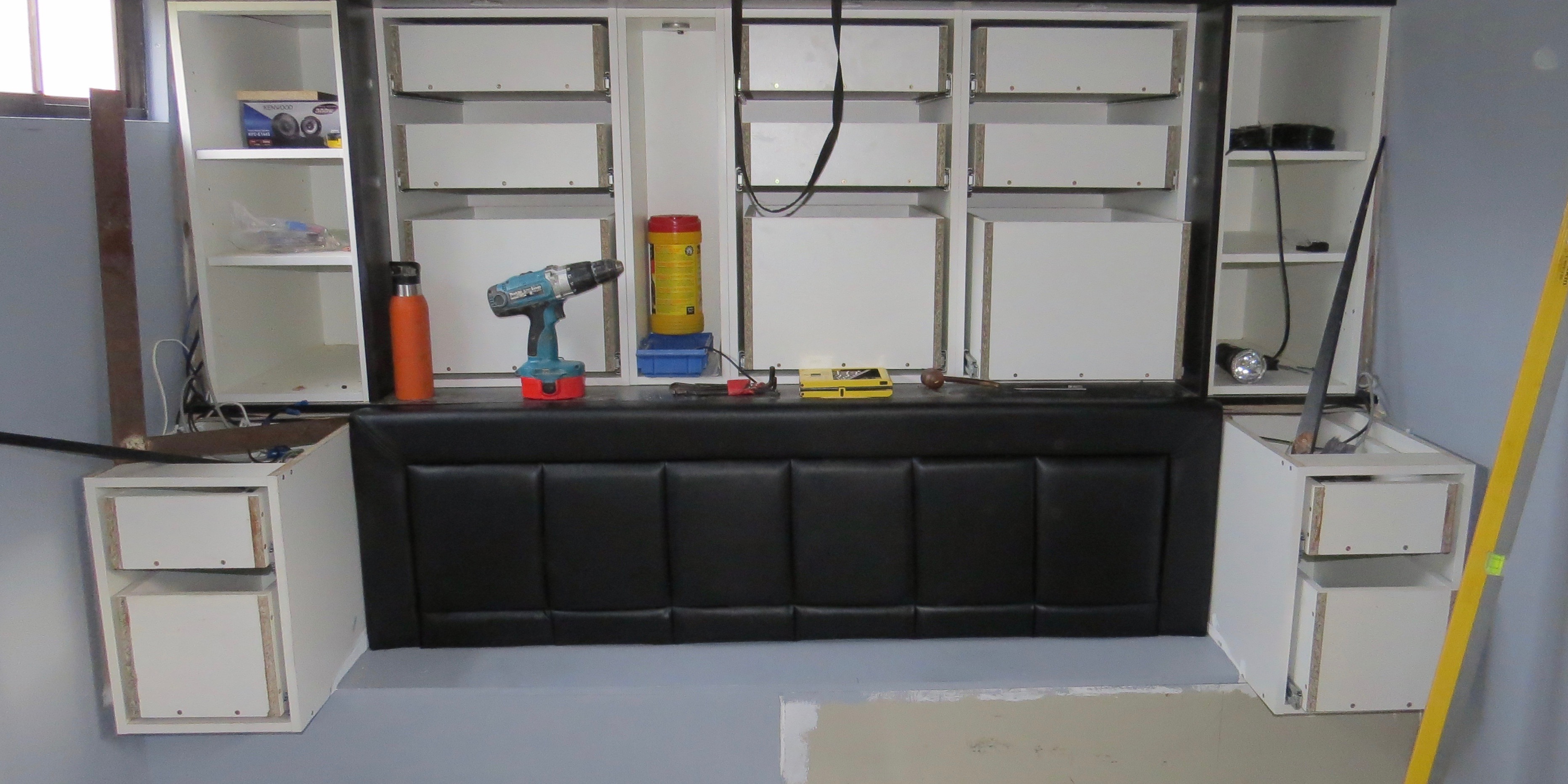

One down one more wardrobe to go

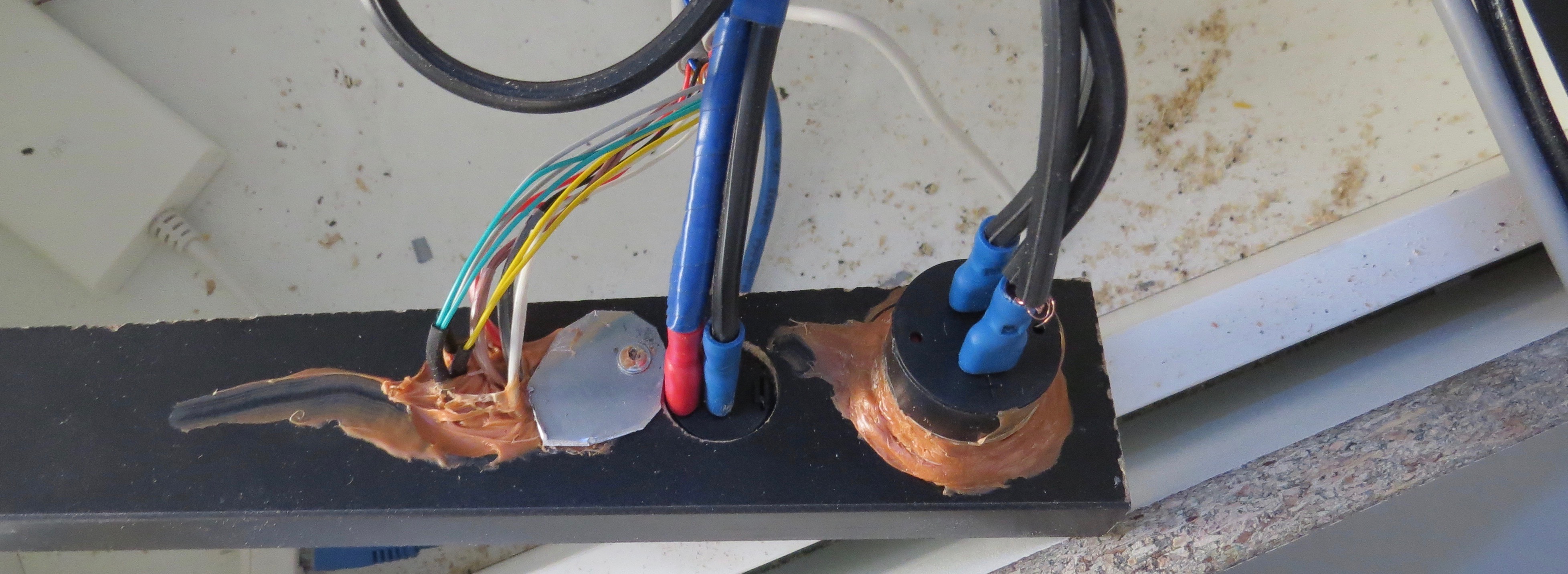

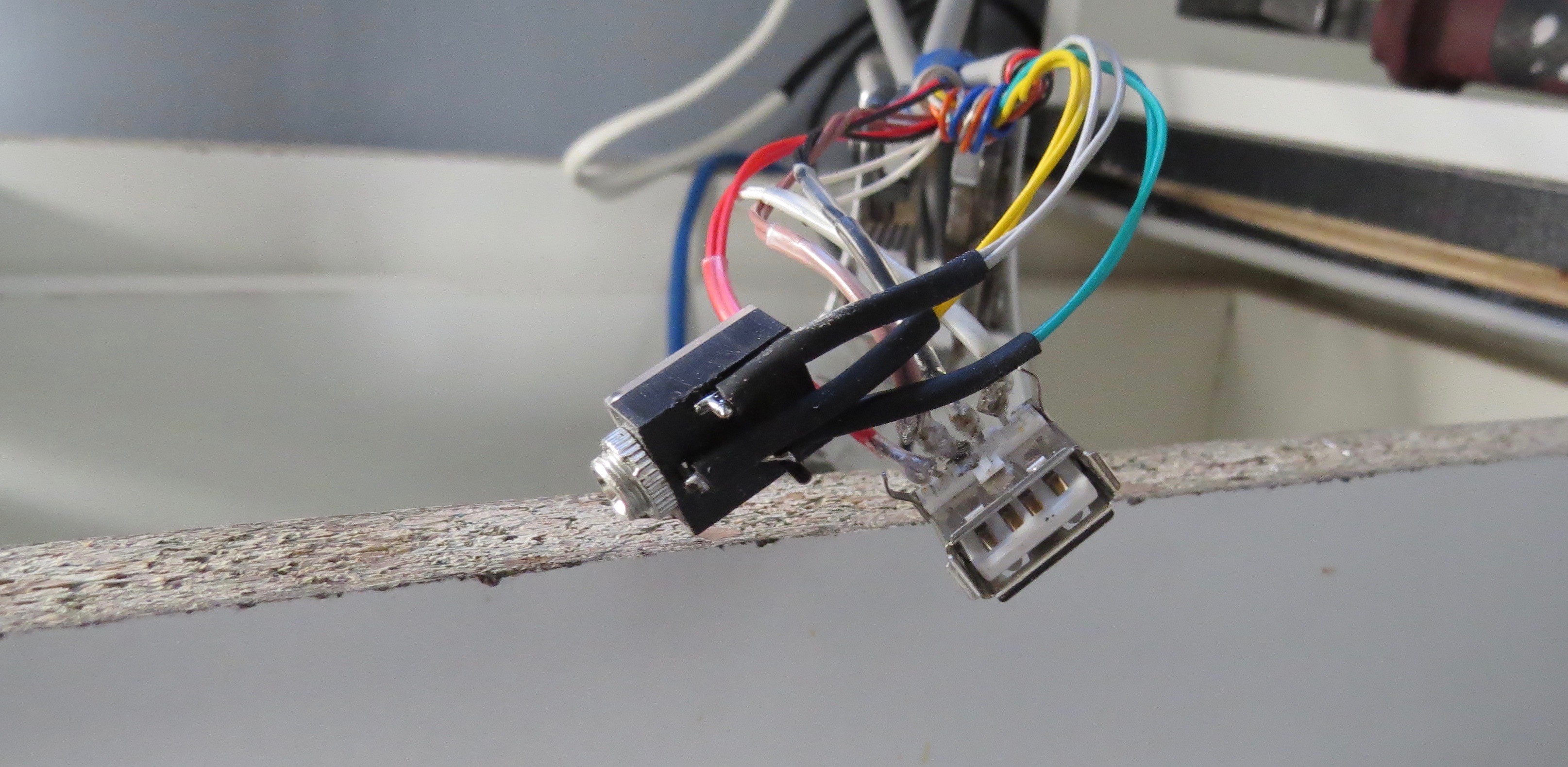

I must say it does get better on the second one as you know not what to do already. This side will also have the stereo fitted above the wardrobe as well as a speaker, so I’ll have lots of wires to play with here. The switch for the bedroom lights will be on this side that will only be 12v for the LED light strip’s.

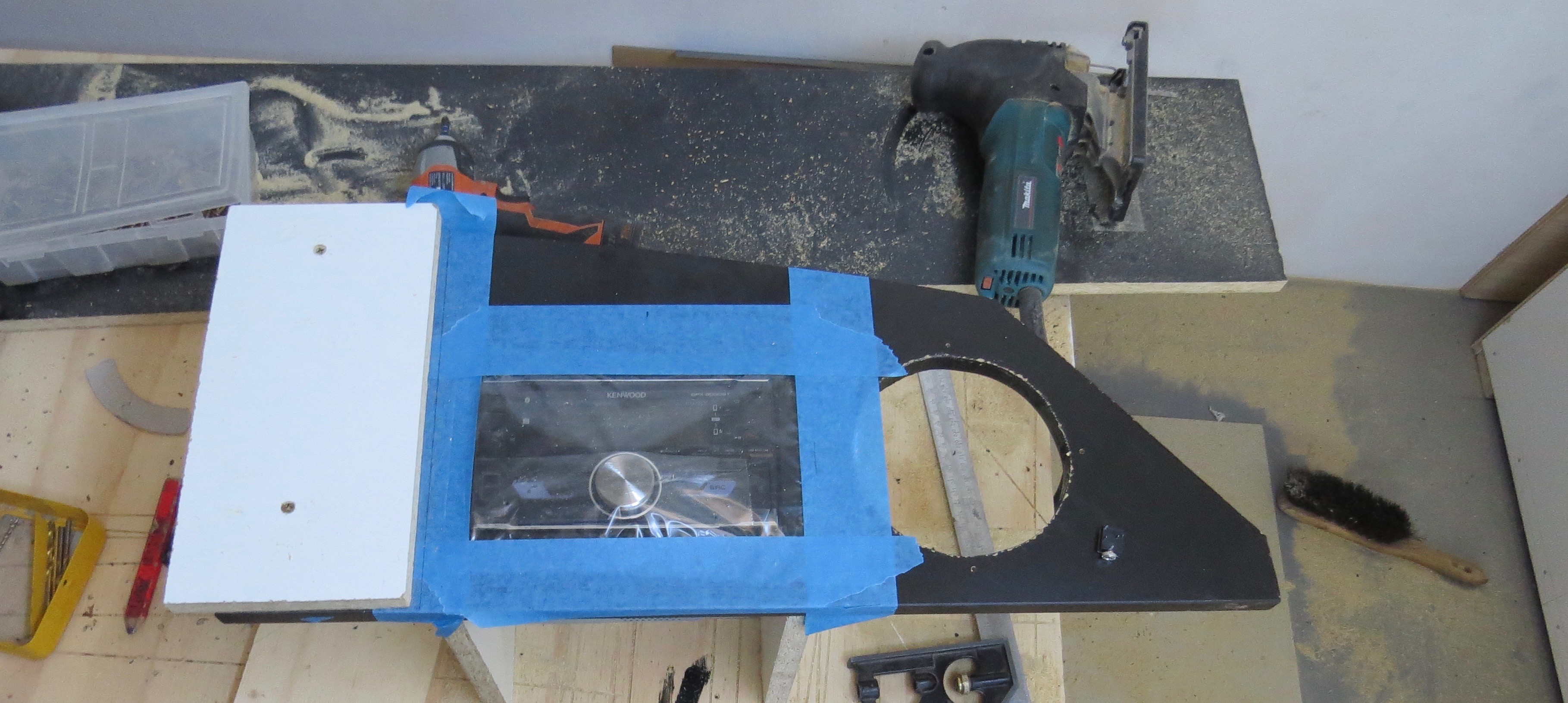

Stereo time

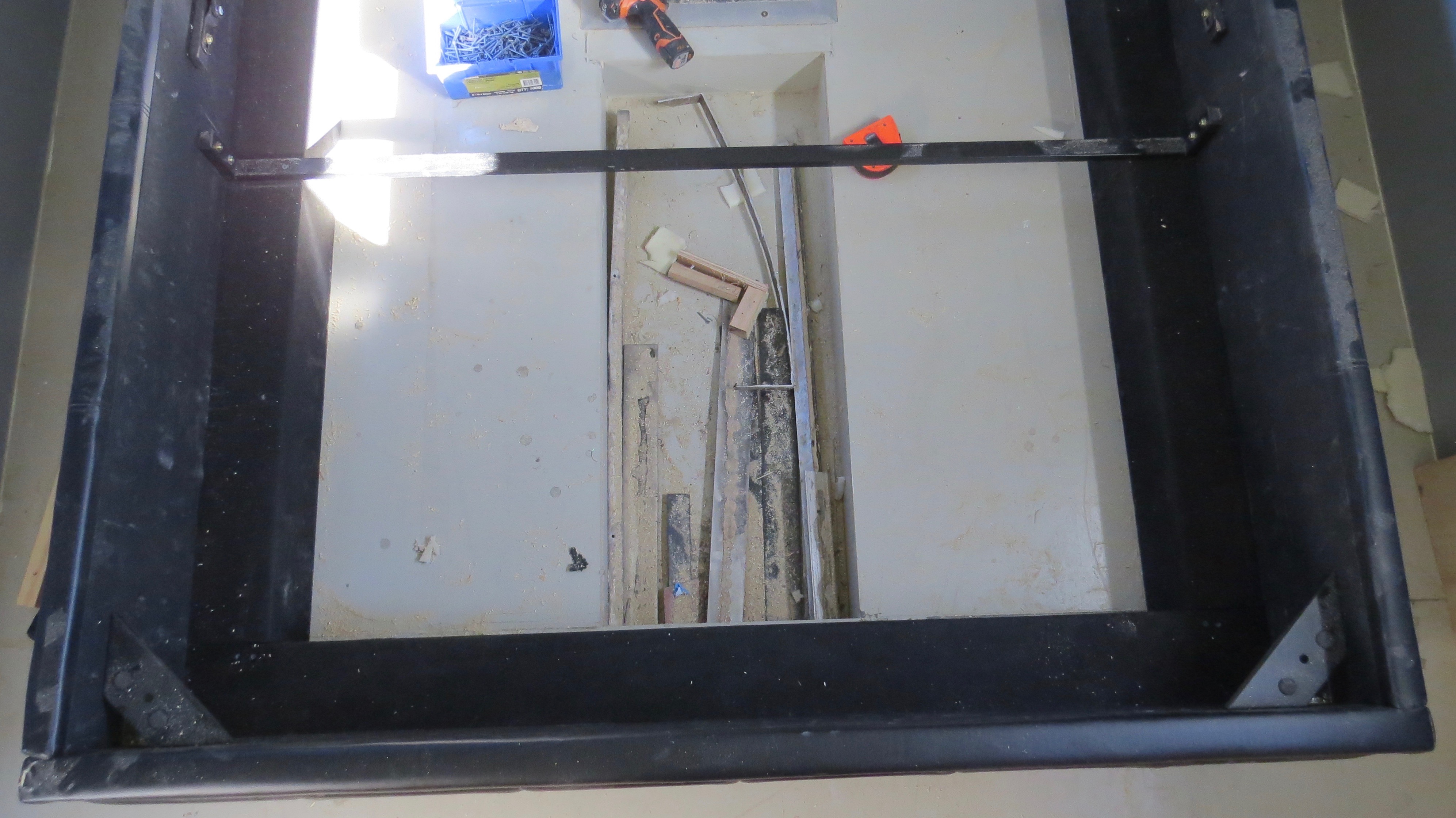

Got to have some tunes in the bedroom, so with a bluetooth stereo we can have sound for our phones or the laptops when watching a movie in bed. So it’s time to put the wardrobe on this side as well as fit the stereo so I can totally finish off the wardrobe.

Finishing it off now

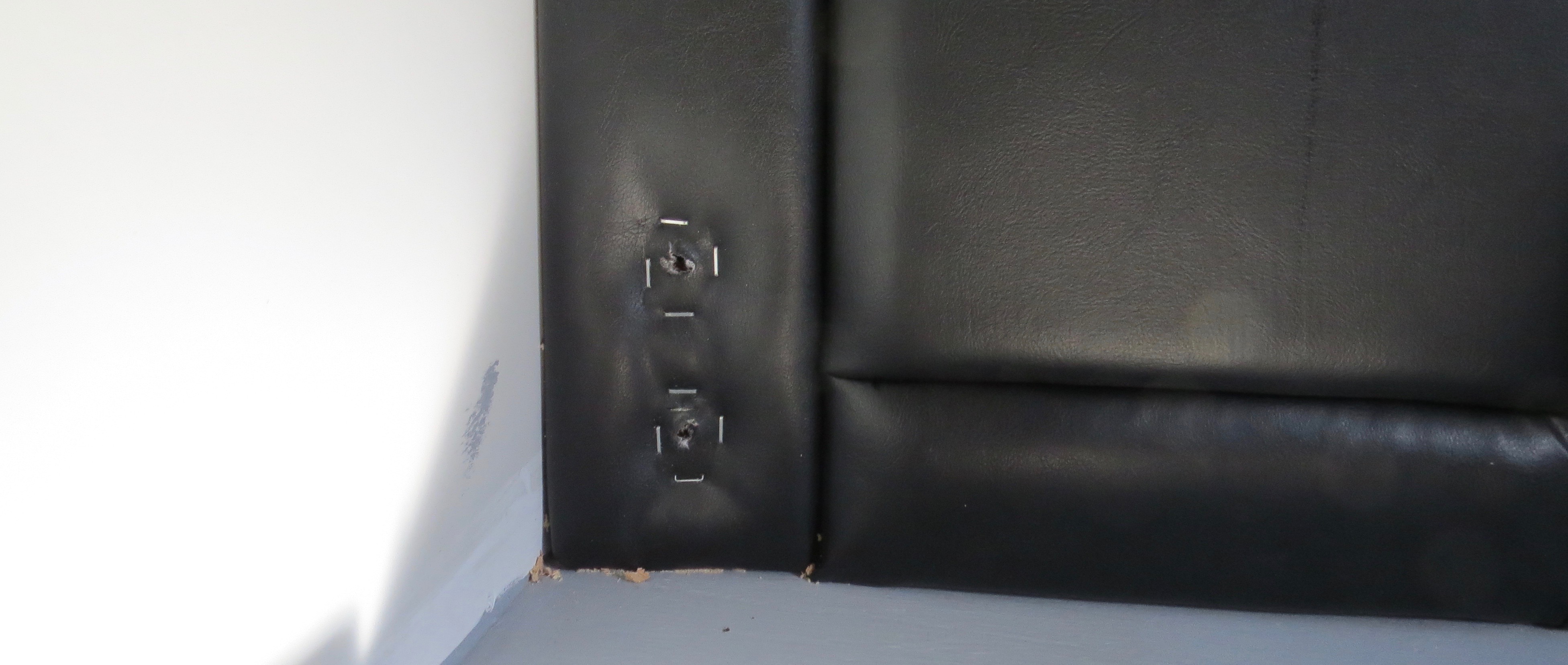

Now the stereo’s in place Charmaine spotted a space behind the stereo that she said would be good for more storage. Looks like I’ve got to make an other cabinet as well, it will all so give us access to the stereo if we need to….hopefully not though.

Apart from the cabinet, draw fronts and wall cladding the bedroom is finish. We still thinking of ideas for the walls, and will get all the draw / cupboard fronts when the kitchen and bathroom are finish. This way we can get them made up all at once, so that will be in the future some time off, for now.