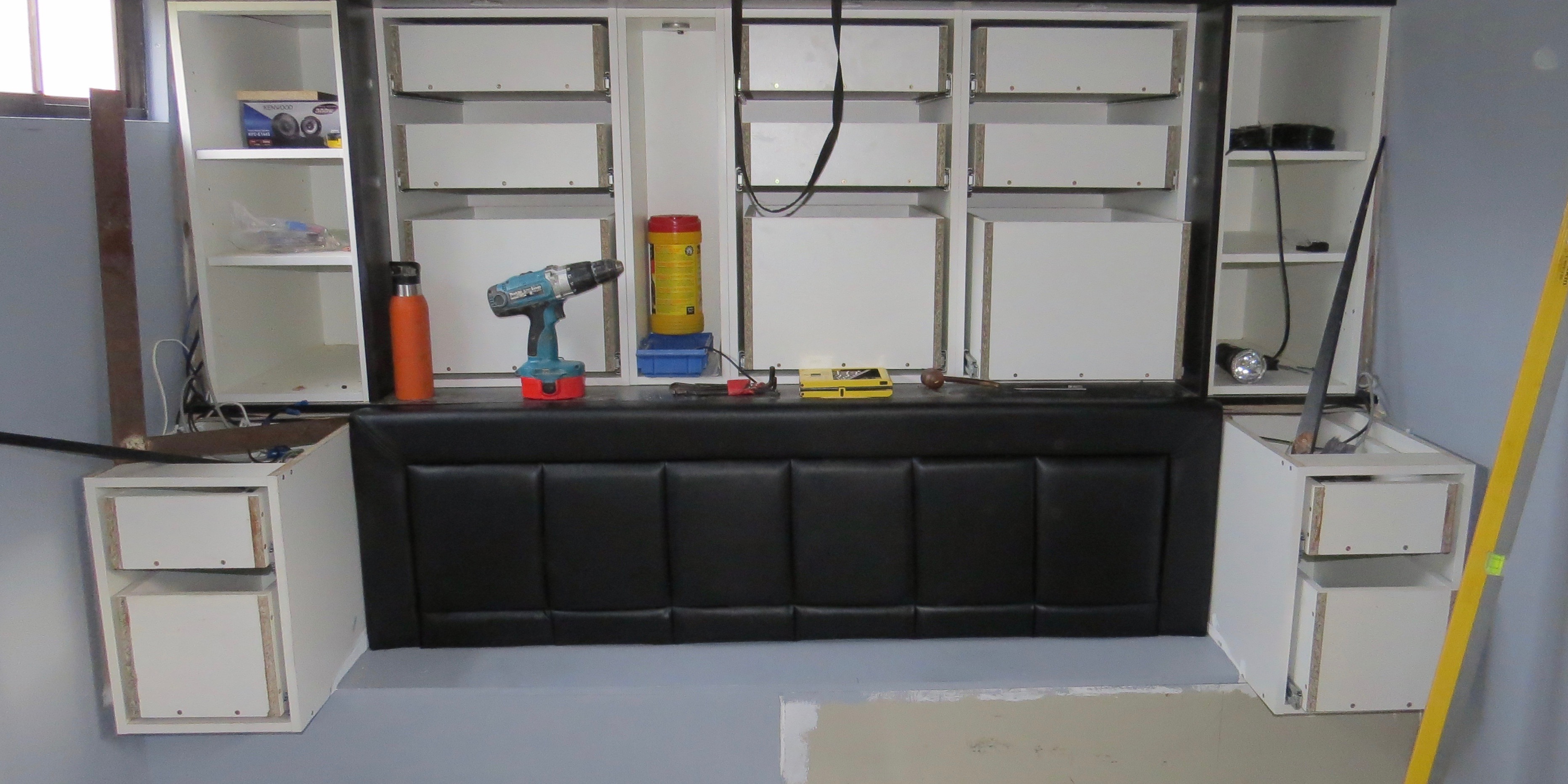

Moving forward and out of the bedroom

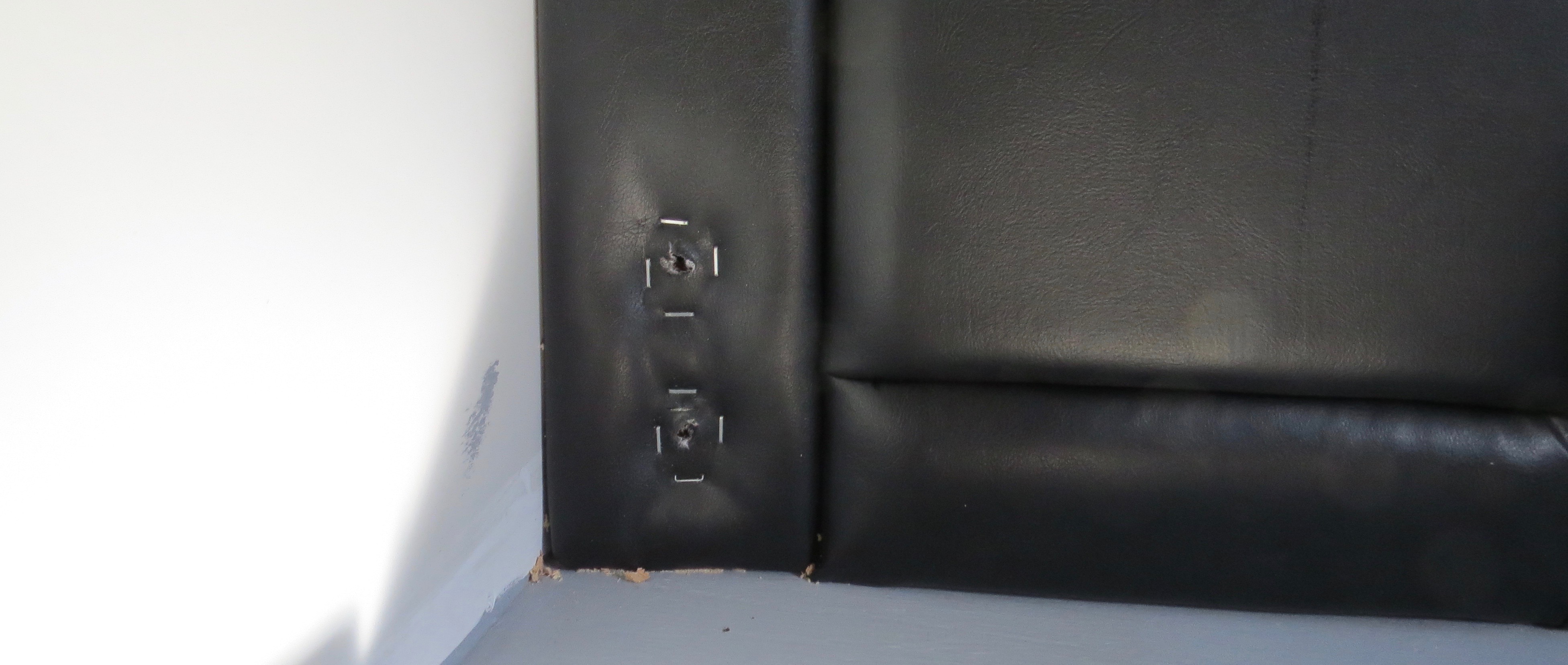

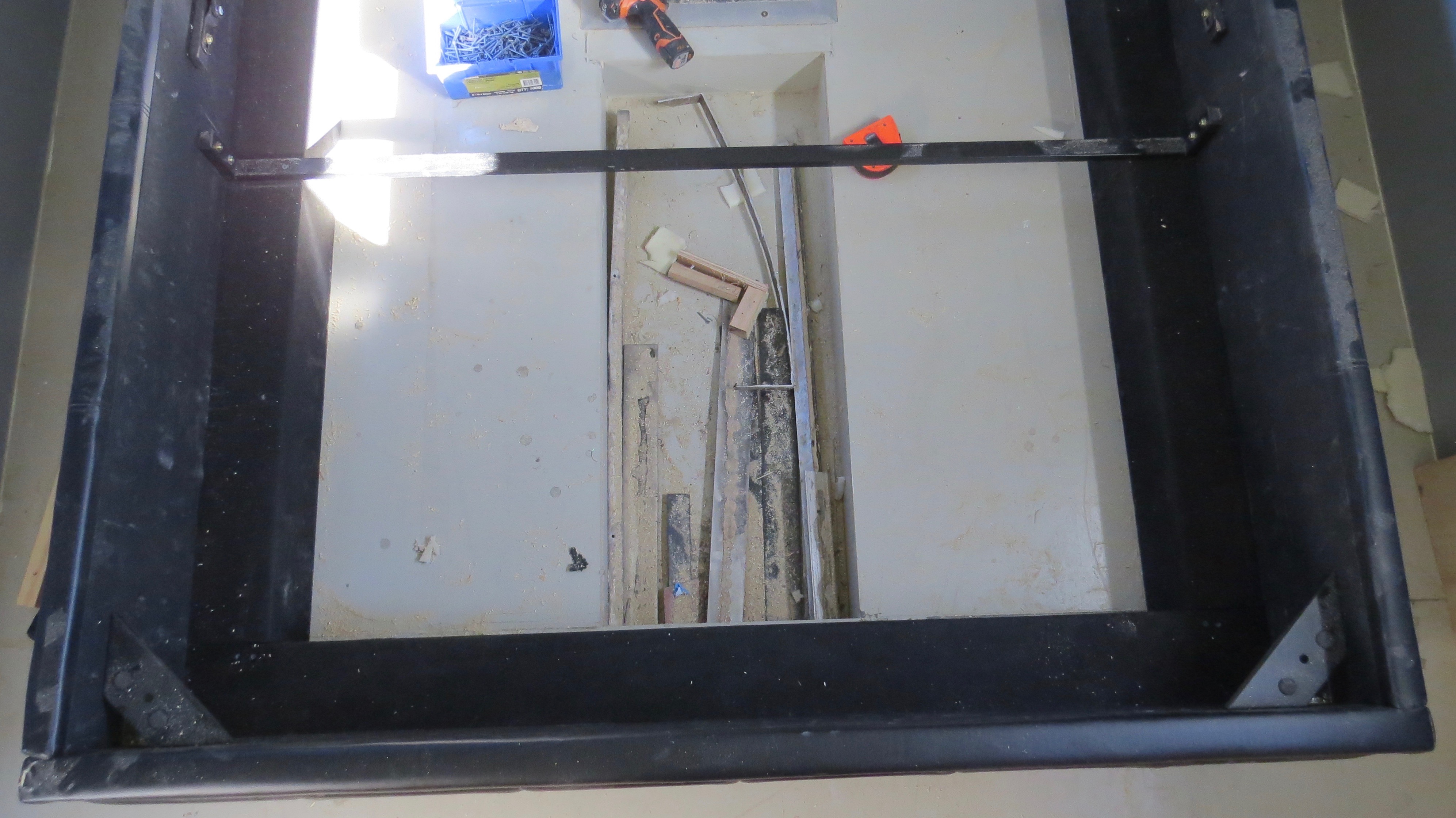

Now into the bathroom we go, after I’d finished the under floor heating it’s time to fix the bathroom floor. The old flooring will have to be pulled up and prepped for the new floor to go down. Until I started I thought it was going to be easy, but I found rusty screws which were holding the floor down as well as it being glued very well in place. This took me a hell of a lot longer than I anticipated, unfortunately. I also had to grind the old seat rail off the wall to get the new flooring into place.

New floor time

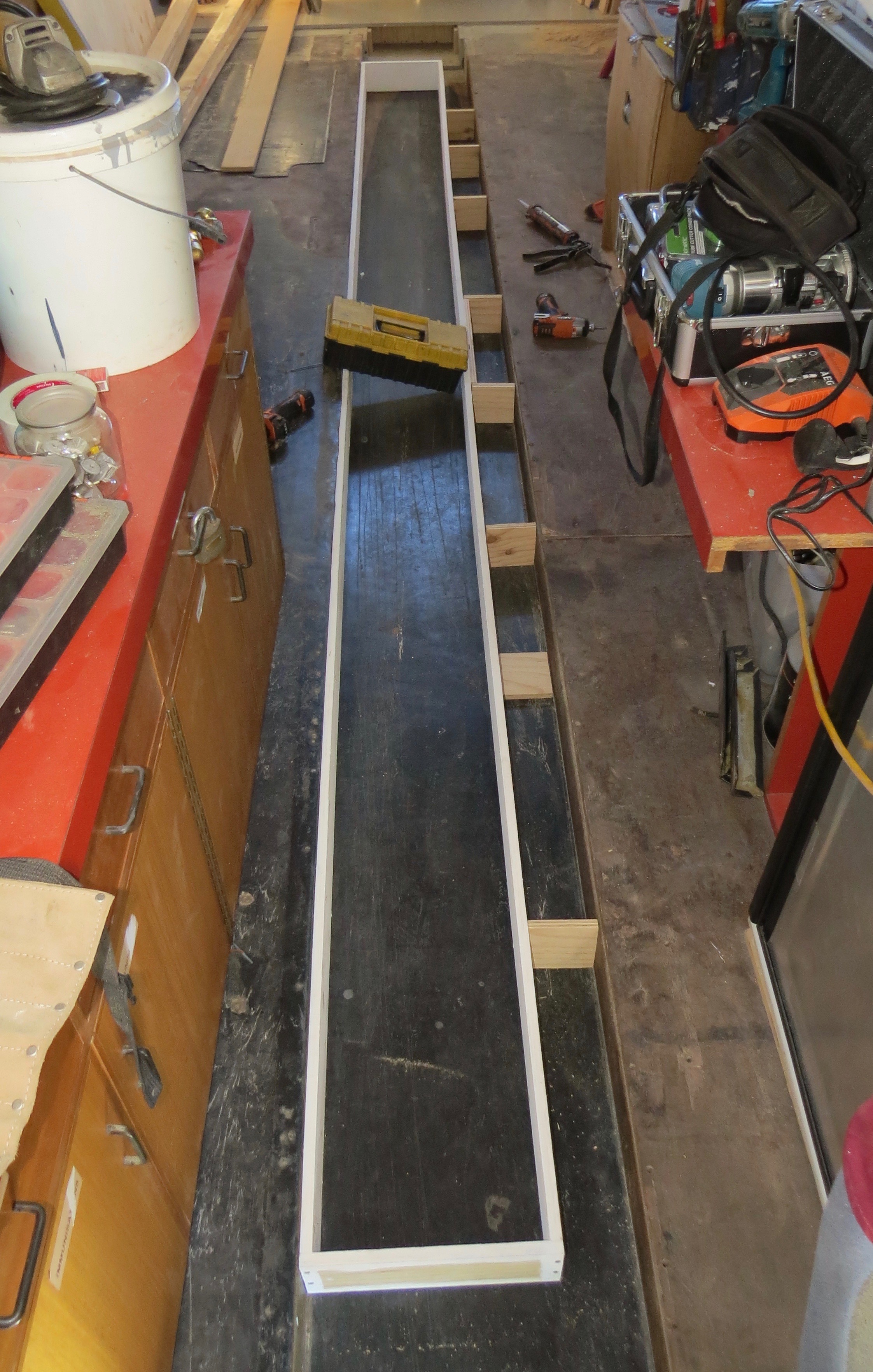

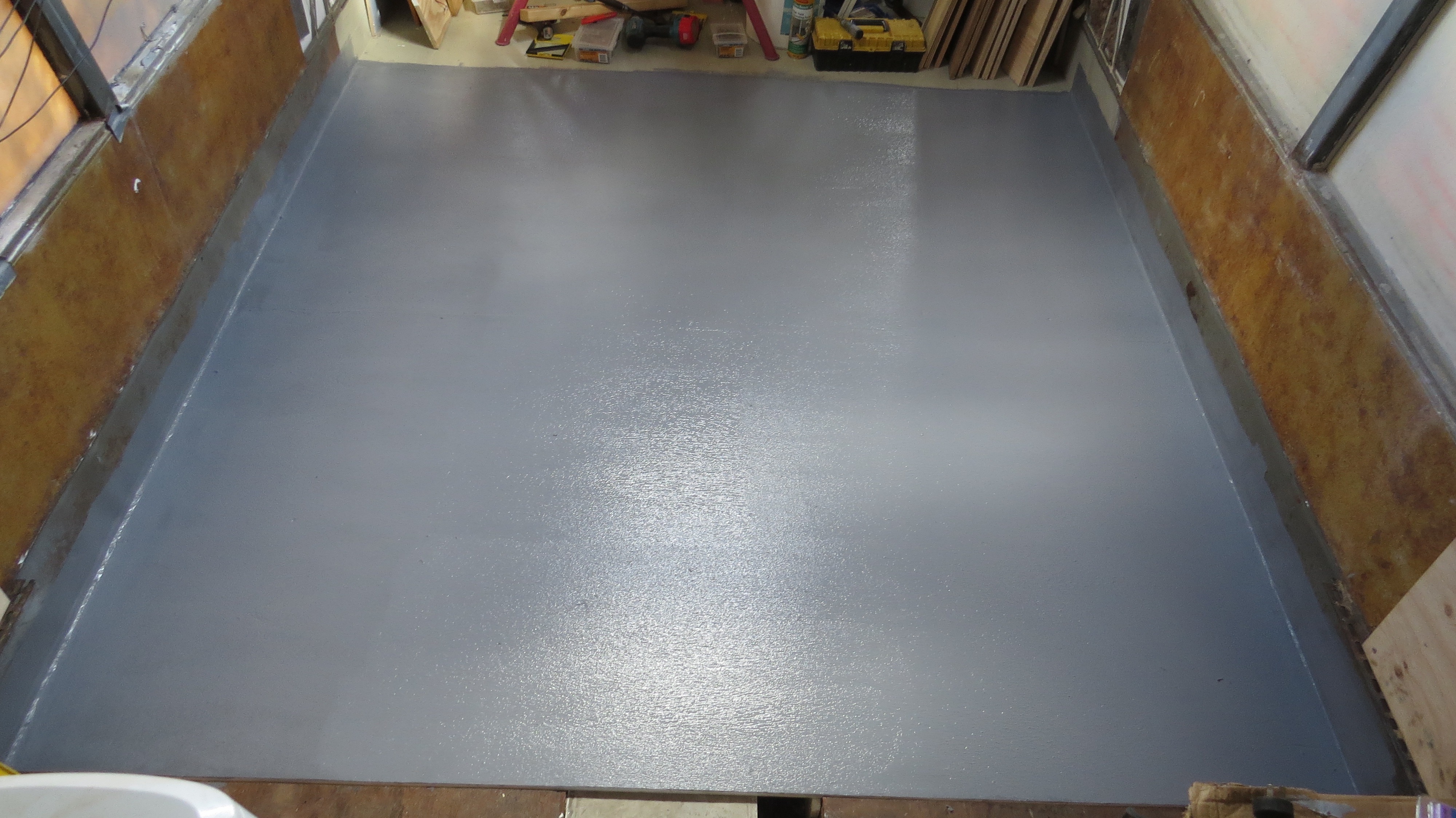

I had already cut the flooring to size using 16mm ply, the old stuff was only 12mm thick. We will also be screwing the same 16mm ply between the supports so the floor will end up being 32mm thick in most places. After letting then undercoat dry it was time to start laying the sheets into place, once again screwing and gluing as we go.

After sealing in between the sheet as well as down each side we put down one coat of water proof undercoat then finished it off with two topcoat’s to seal it off, no water getting through here now.