Back To The Air-Conditioning

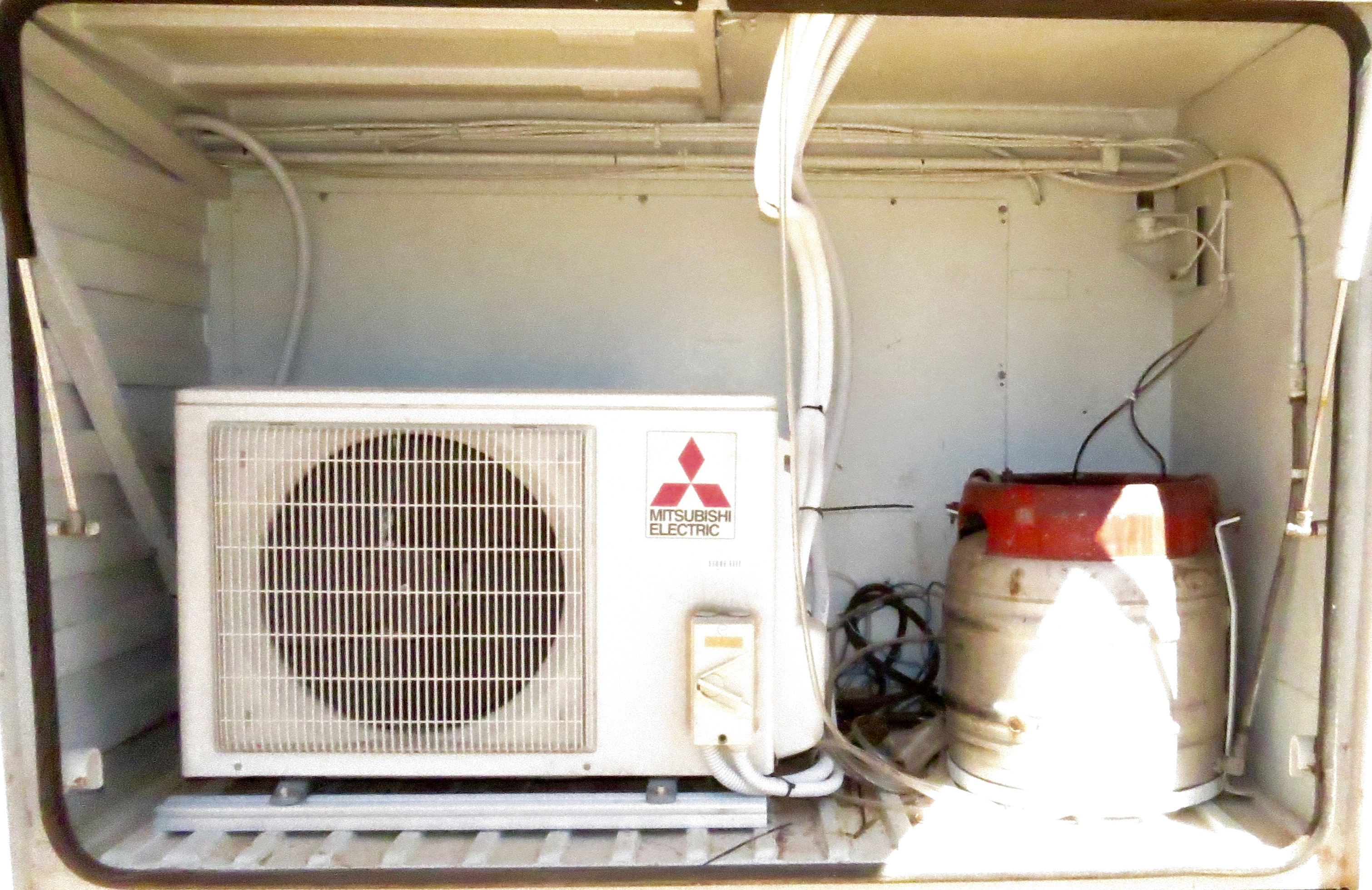

We had already done the first part of the work on the bedroom ceiling, but to finish that job. We had to rip the rest of the old air-con off the roof. I started with getting the sola panels off first, then remove the cover plates.

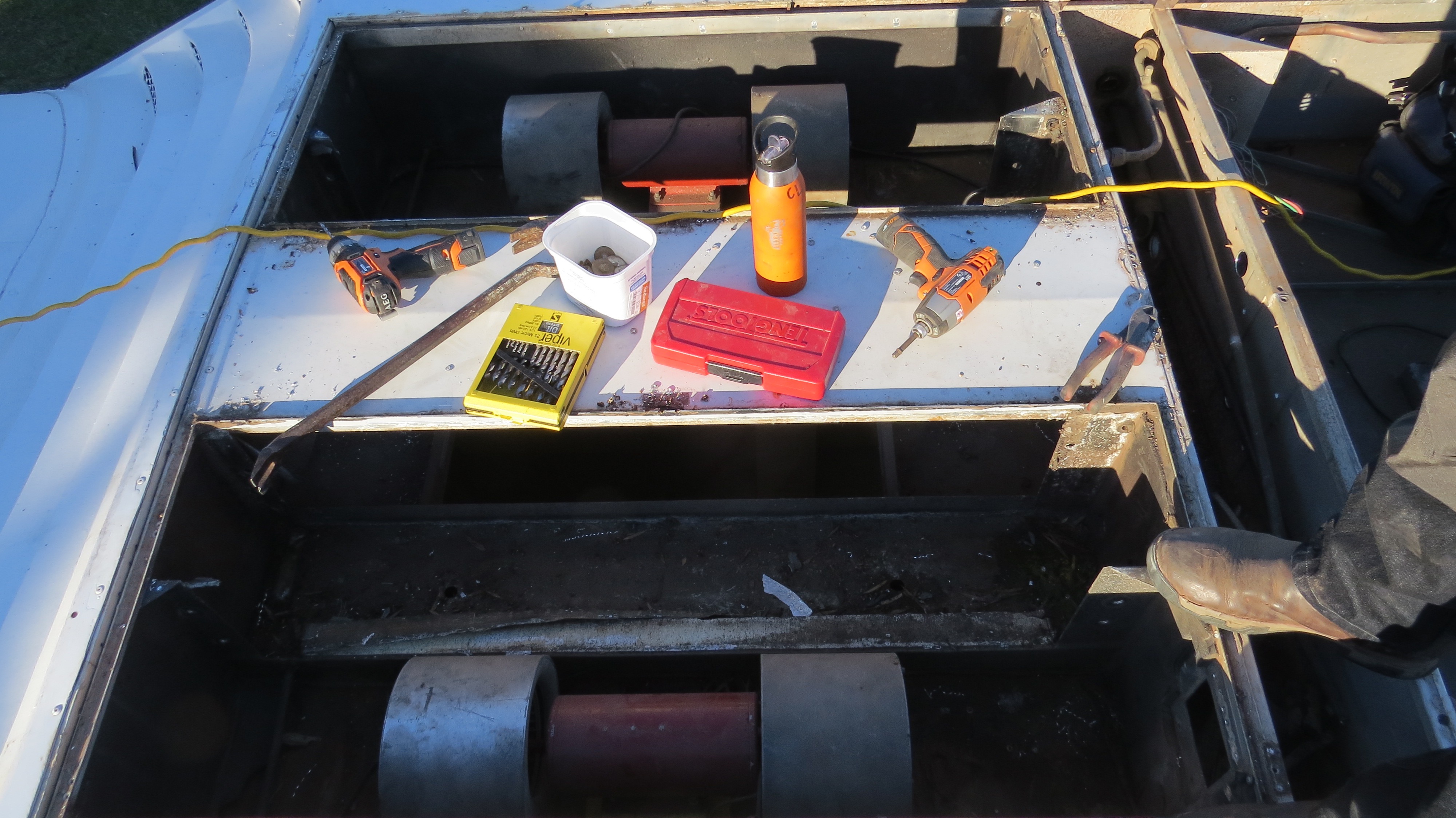

This will be the last time it will look like this.

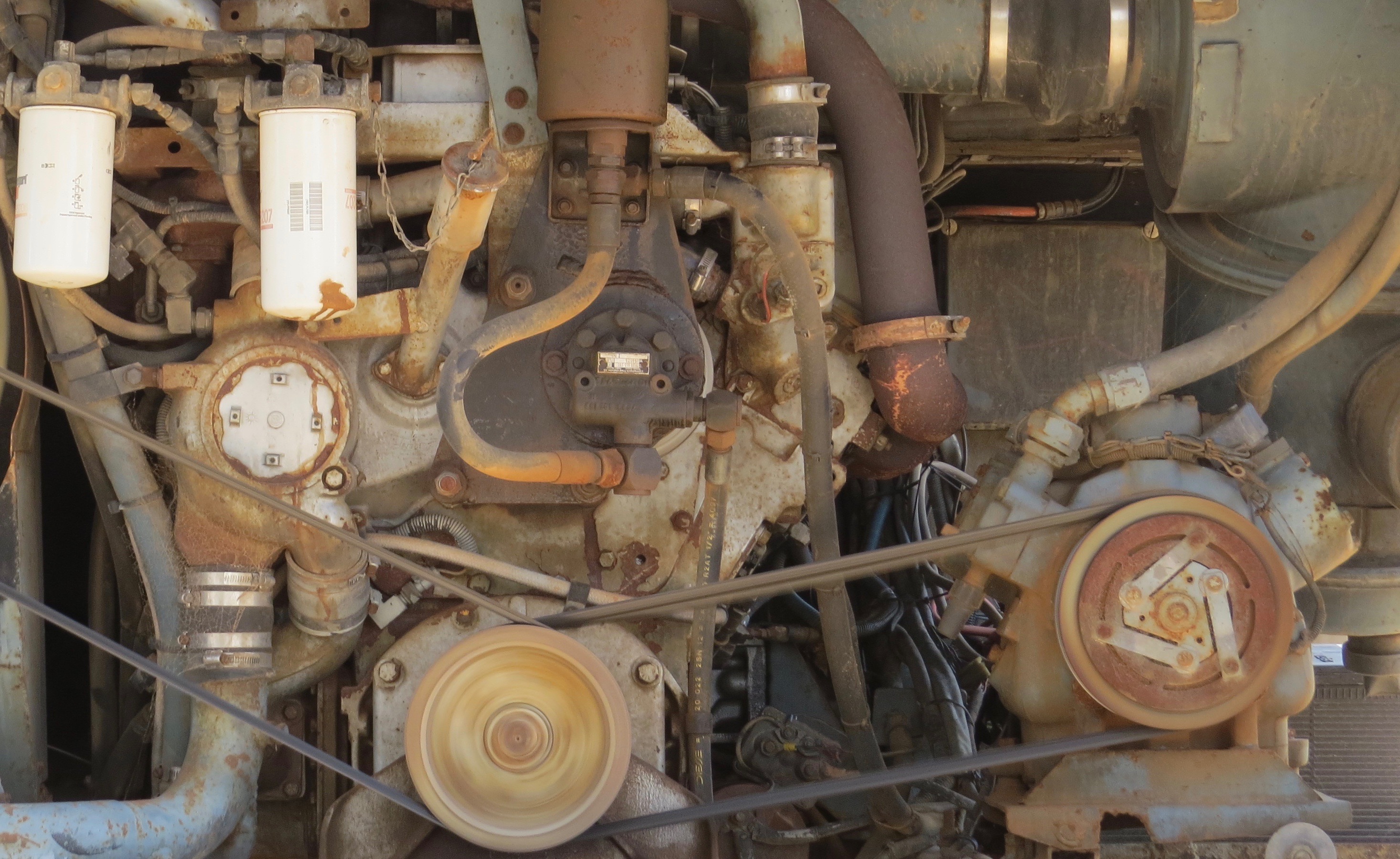

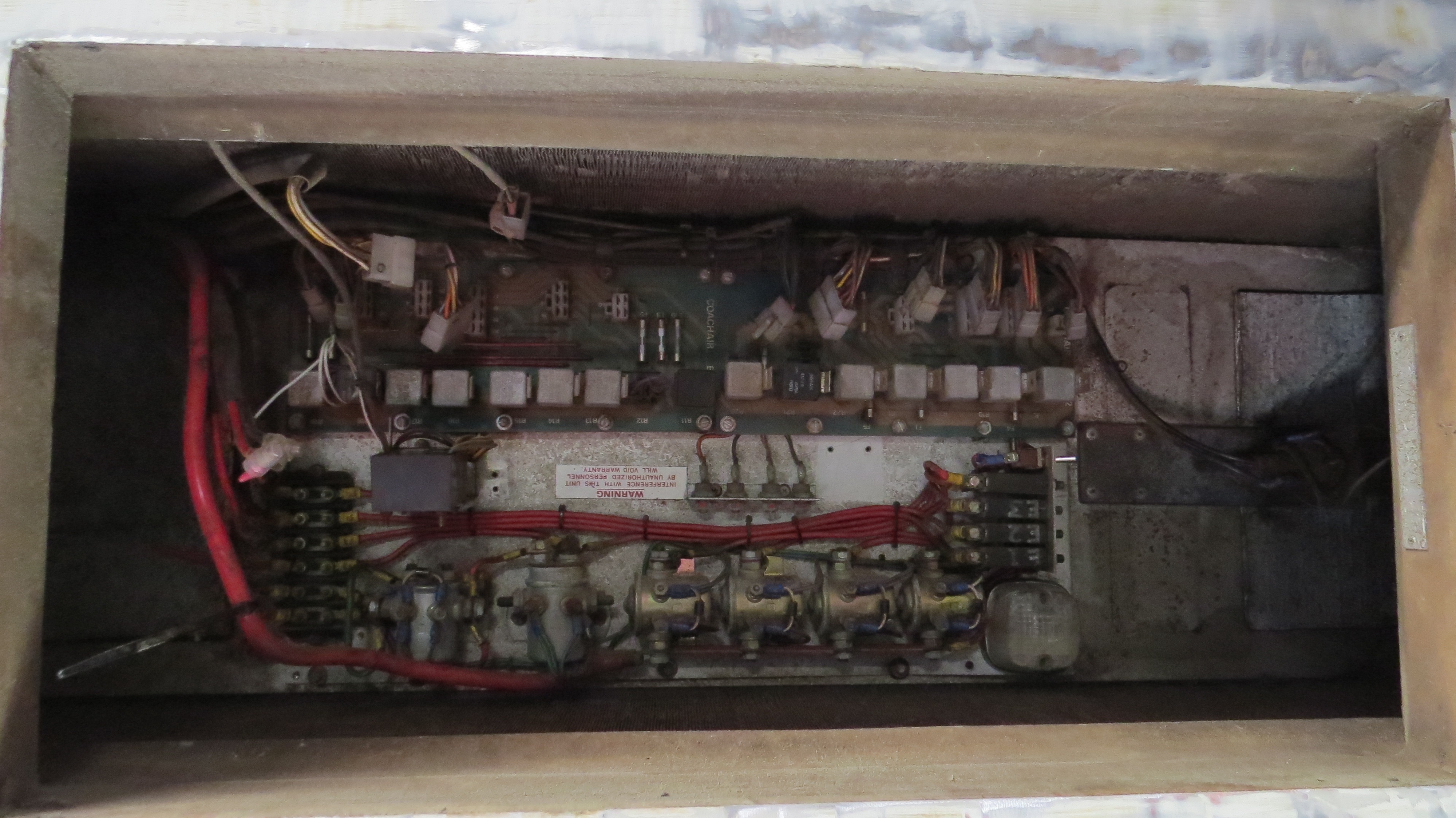

The finished look of this project we will have a roof top deck up here, but not now that is a job for an other day. Now it’s time to remove the evaporator, heat exchange radiators and blowers. Stripping out the copper pipe, heat exchange radiator pipes as well all the electrical pits.

More Stuff For The Scrap Yard

I did a trip to the scrap metal yard with all the copper, brass, evaporator and the heat exchange radiators. It’s always good to get some money back, that lot gave me $145 to put back into the project. Next will be cutting out all the aluminium that we don’t need off the roof air-condition area. I all ready have some that we have removed so that we will have an other trip to the scrap yard soon.

Did I see rain?

Well it did start raining on and off for a week, lucky we could put the covers over the holes and with some buckets inside it didn’t get too wet inside. This means I went back inside to do some more work on the bedroom/bathroom ceiling, while it rained but thats an other blog.

1st blog on THE OLD COACH AIR CONDITIONING