Is it a nightmare or a dream.

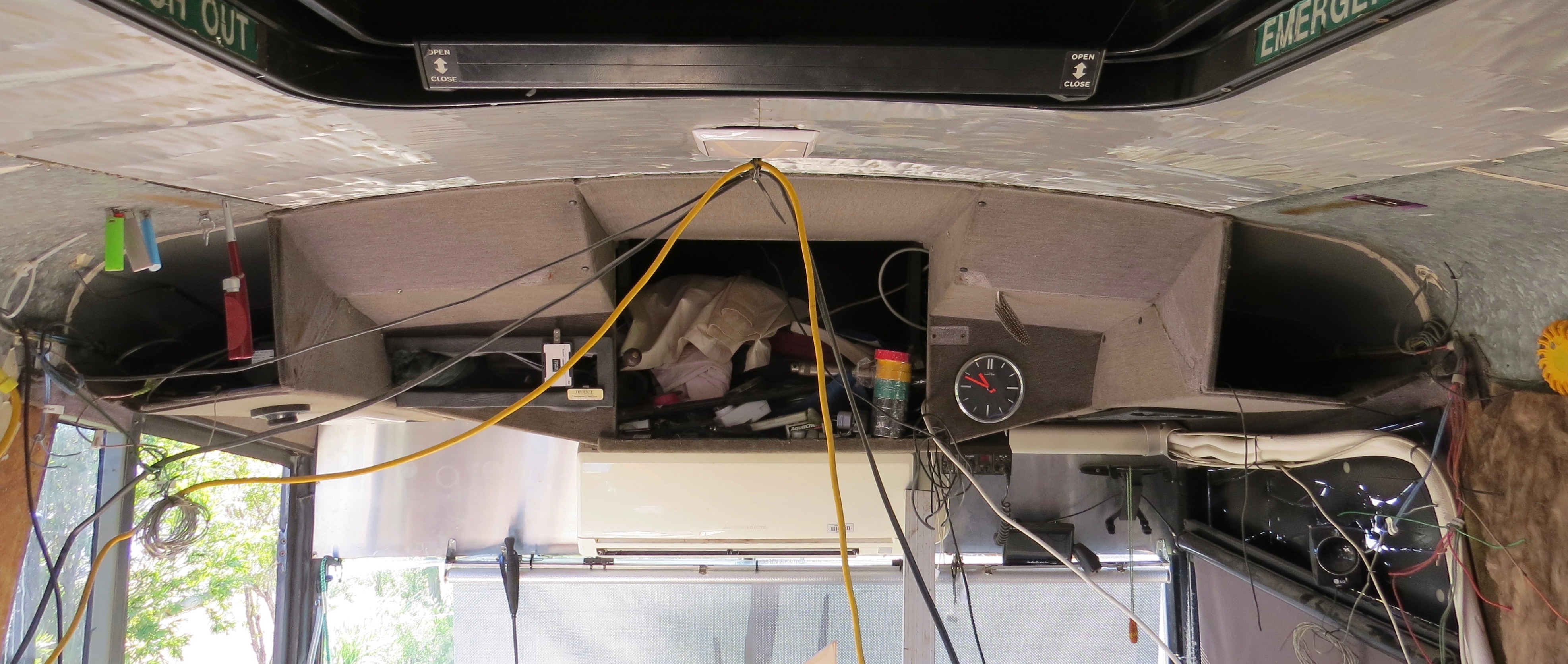

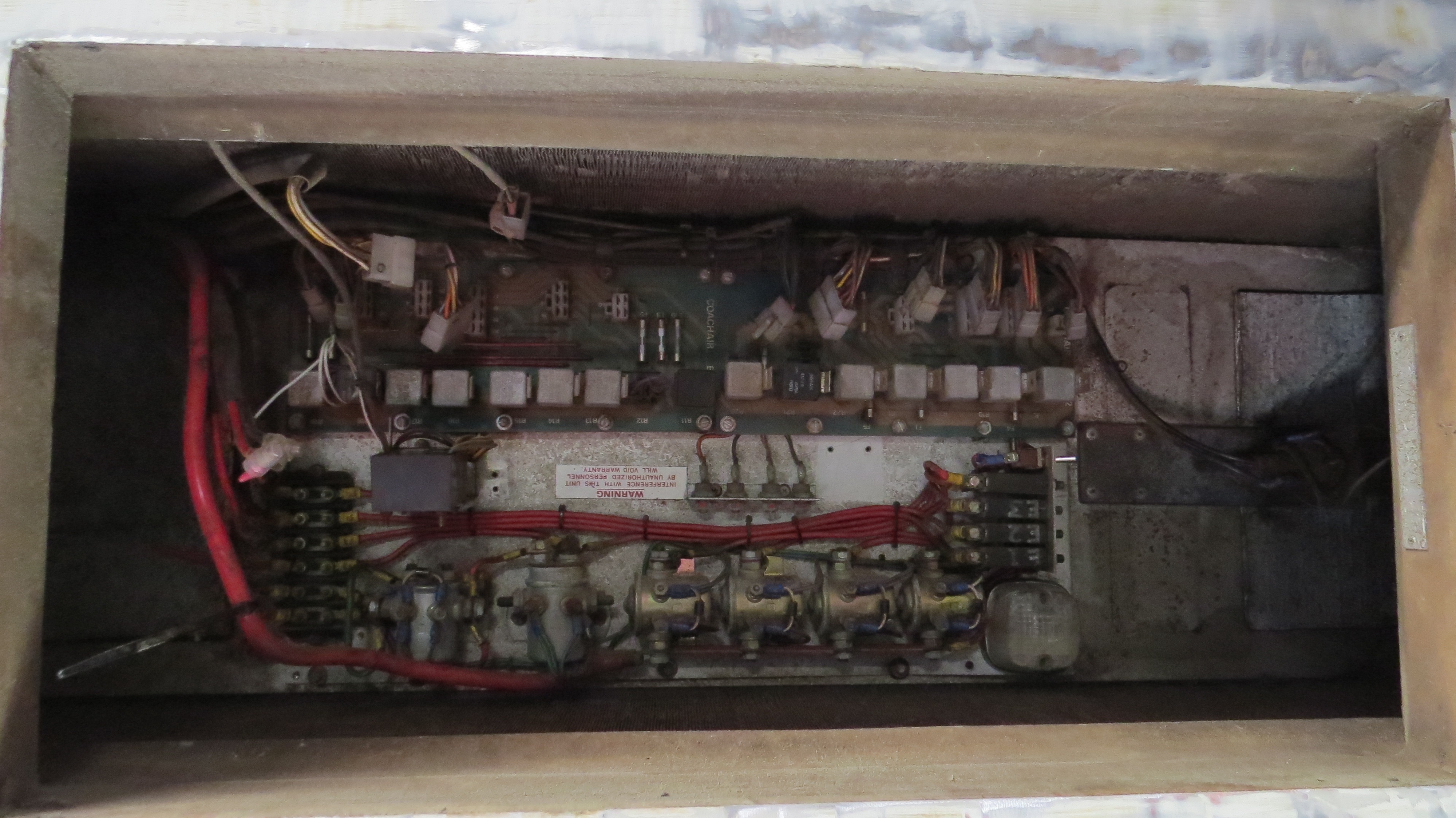

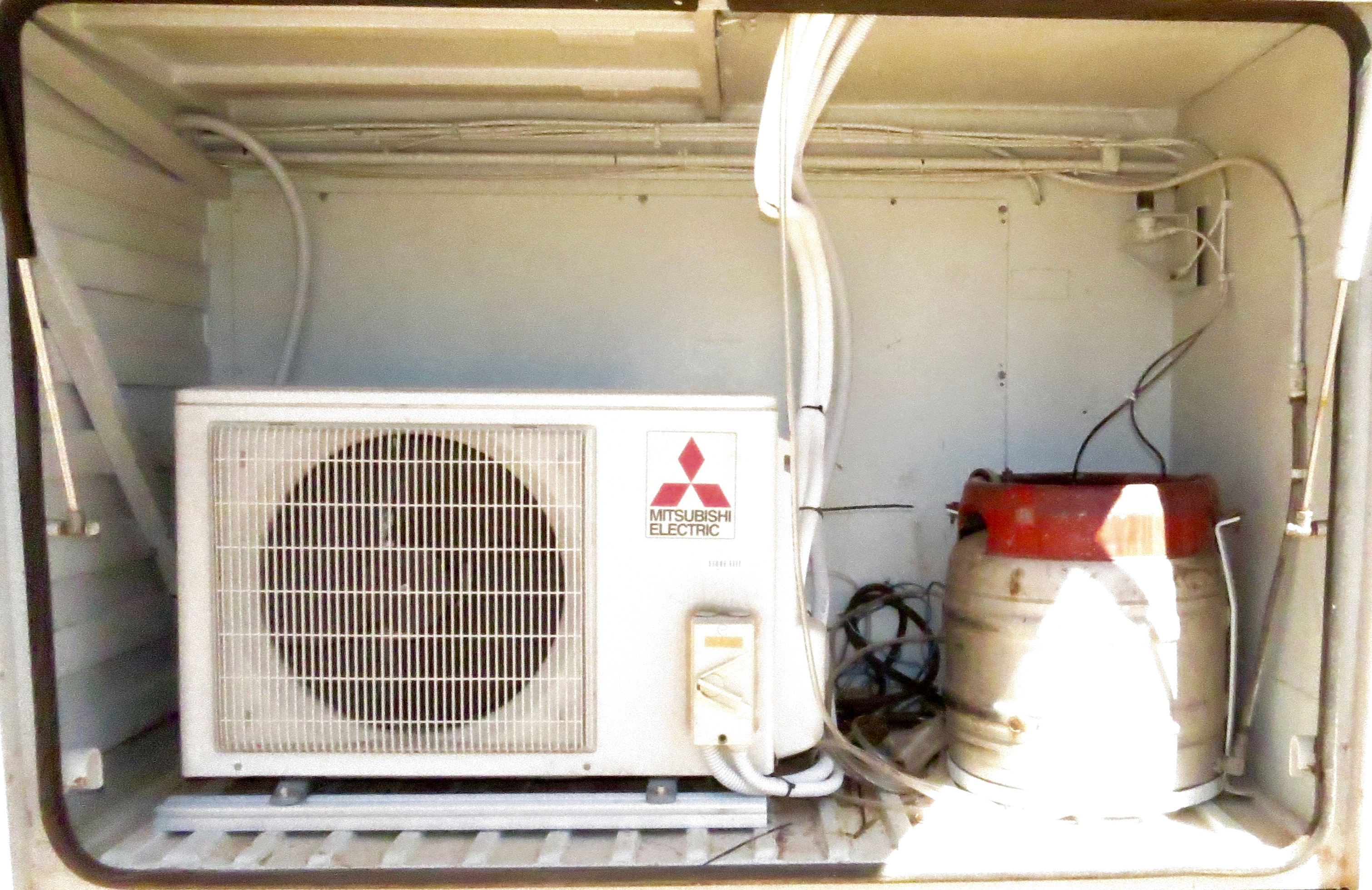

Yes it is a dream, just a lot of work to get there. With the air-con fitted into place now I can finish off all the small bits still to go. So back out with the tape to mark out the next pice to be cut.

I have also covered the top of the driver side window above the pull down shad with insulation behind it, because the heat that comes off the window when the sun’s on that side make’s like not that nice.

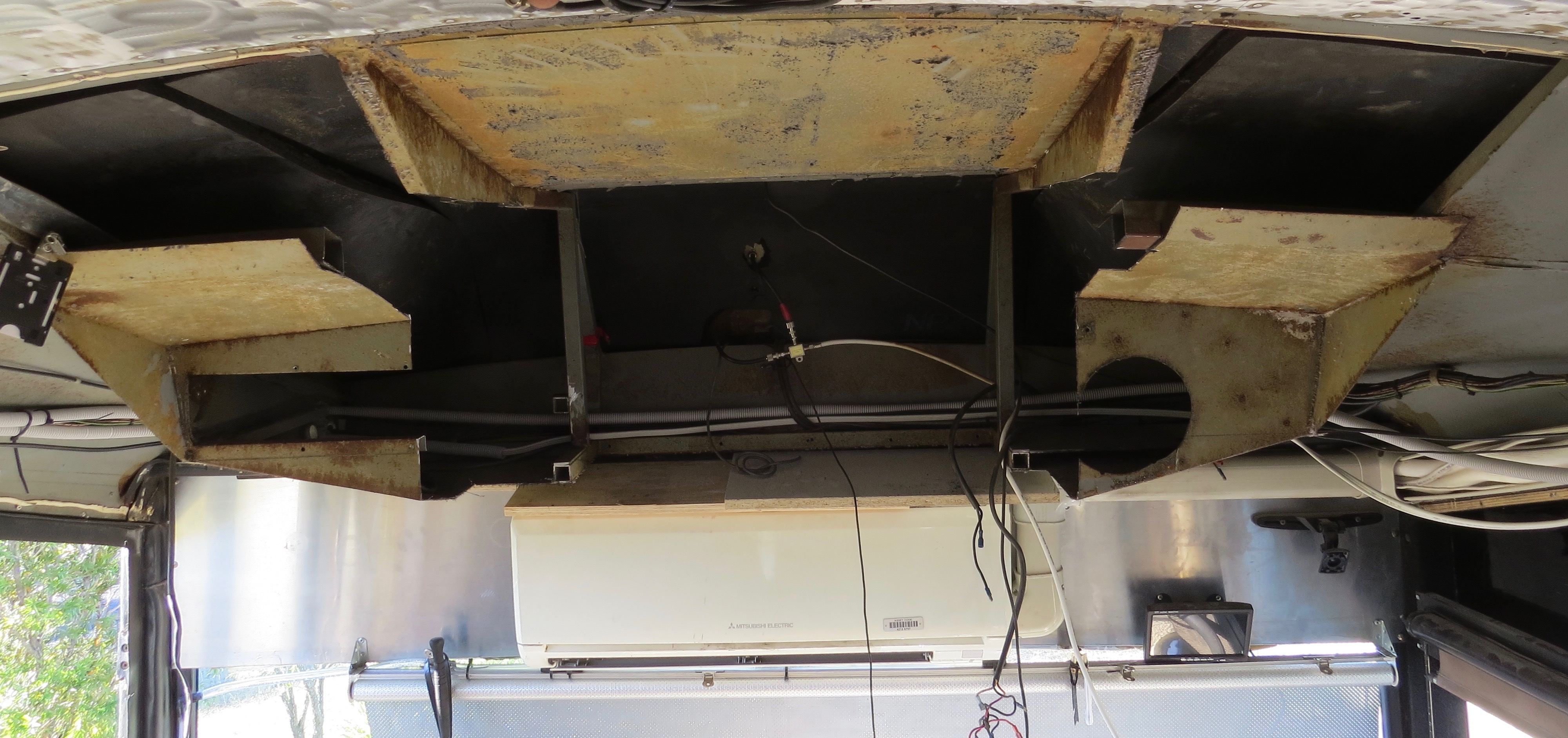

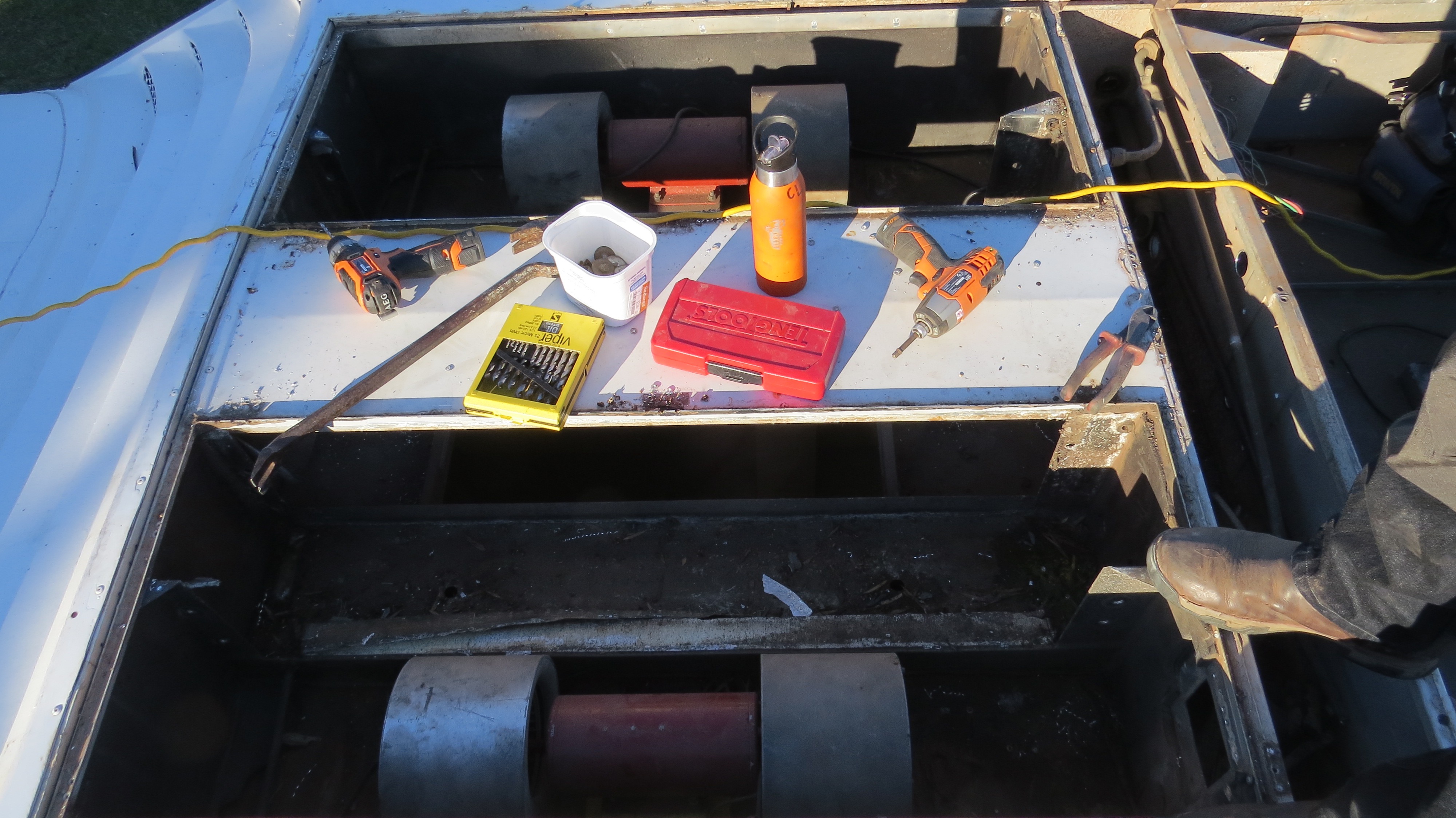

Now to cut more ply to fit into place across the front to finish off the bottom of the air-con housing. Making every measurement count as I don’t wont to stuff a pice of ply up.

The things you do by your self

Now all I have to do is get it into place, glue & screw it by myself as Charmaine’s at work.

Now to tidy up the little bit’s to finish it off across the bottom of the air-con.

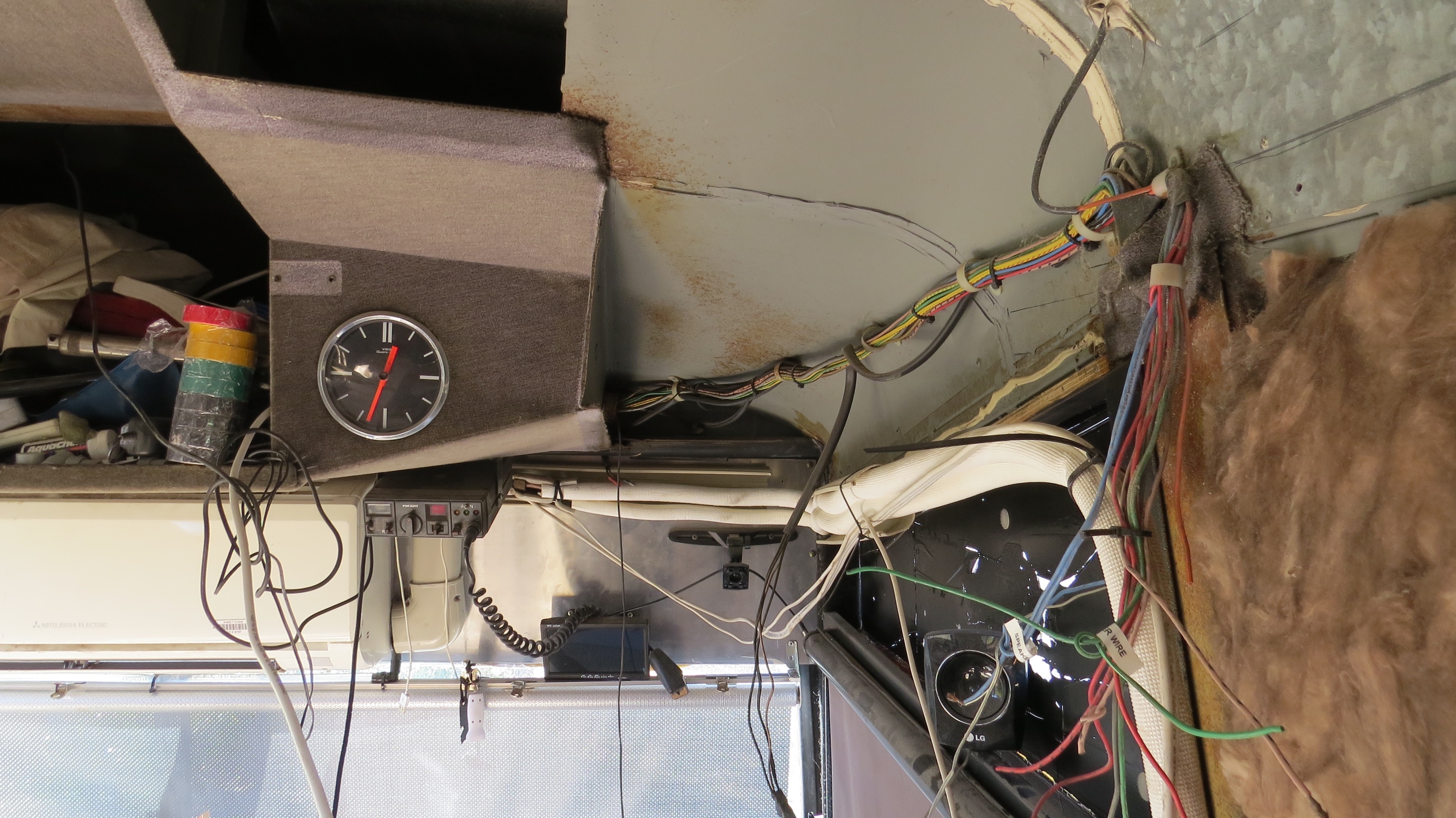

This will be covered later on and have a panel to fit the GPS, two-way and the reversing camera screen as well as anything that I think of later.

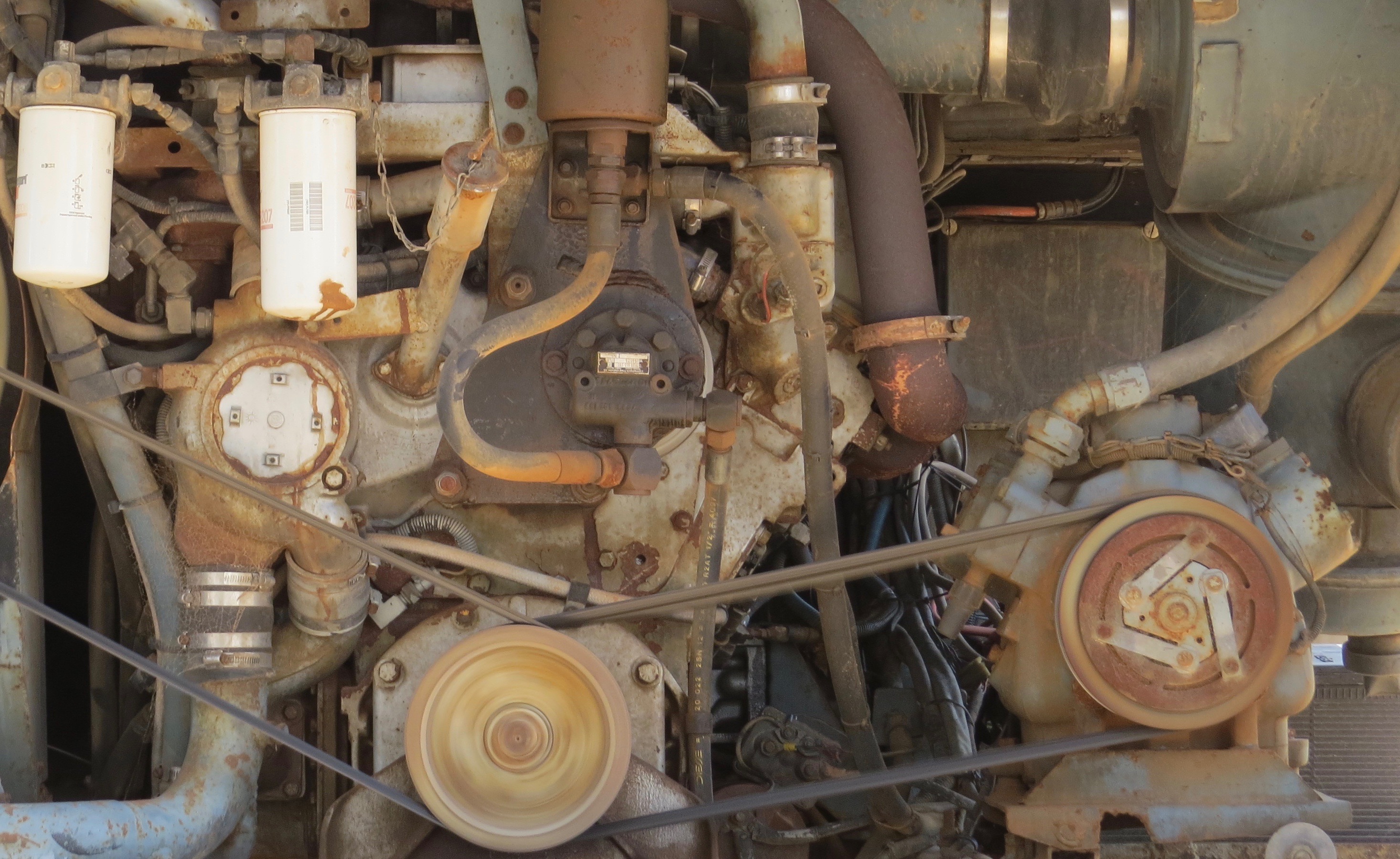

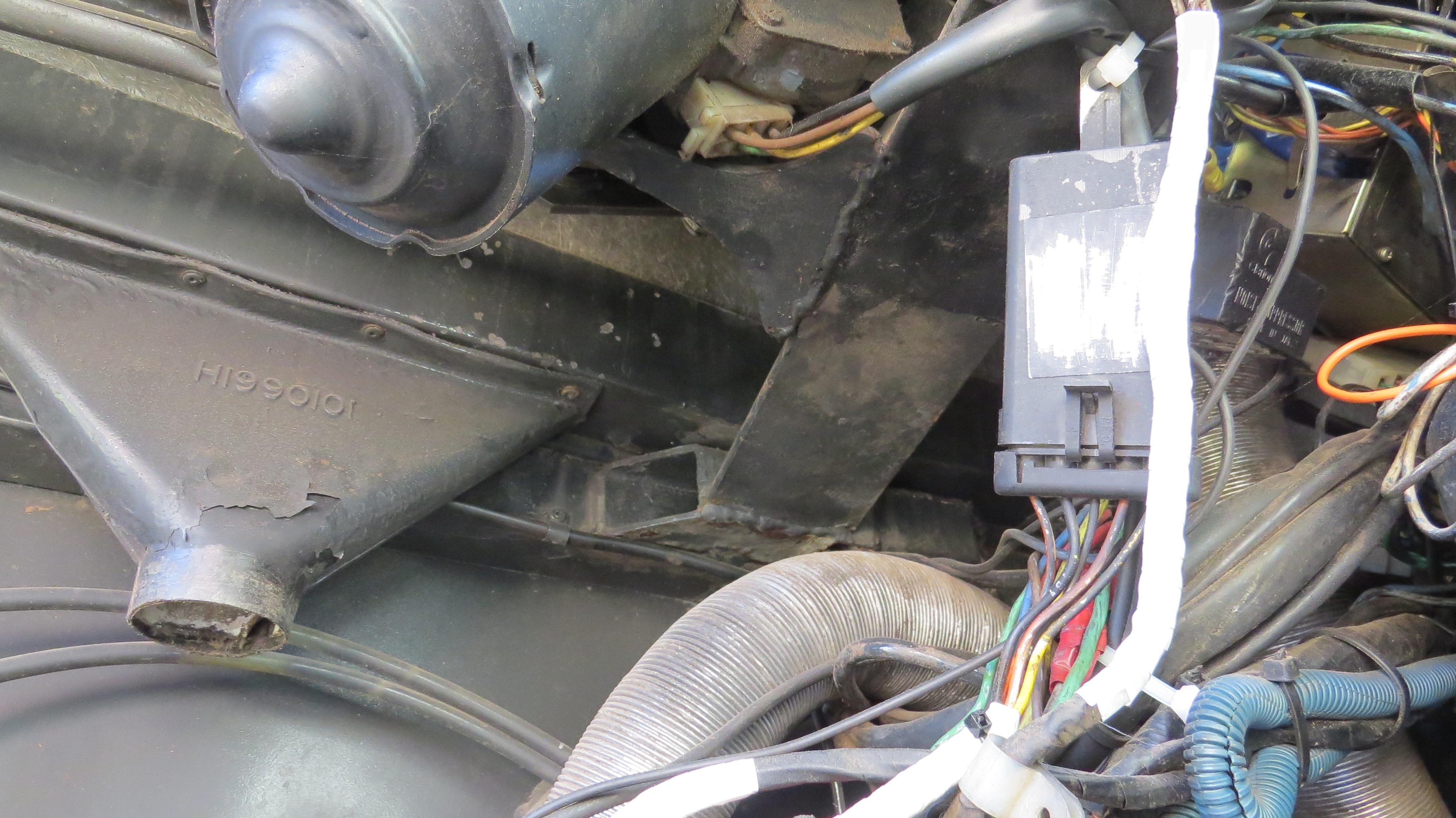

The drain for the air-com was fun to put into place. It needs to have a drain on both side’s because when your driving down the road and the coach sways from side to side the water go’s every wear. We found this out driving down the coast from Townsville, They was no problems in the outback because of the low humidity.

I ended up running the drain down through the middle windscreen support bar then through the floor so it will drain out on the ground below the driver’s seat.

Well that’s done thank goodness, even the drain works when your driving down the road.