A Bigger job than it looks

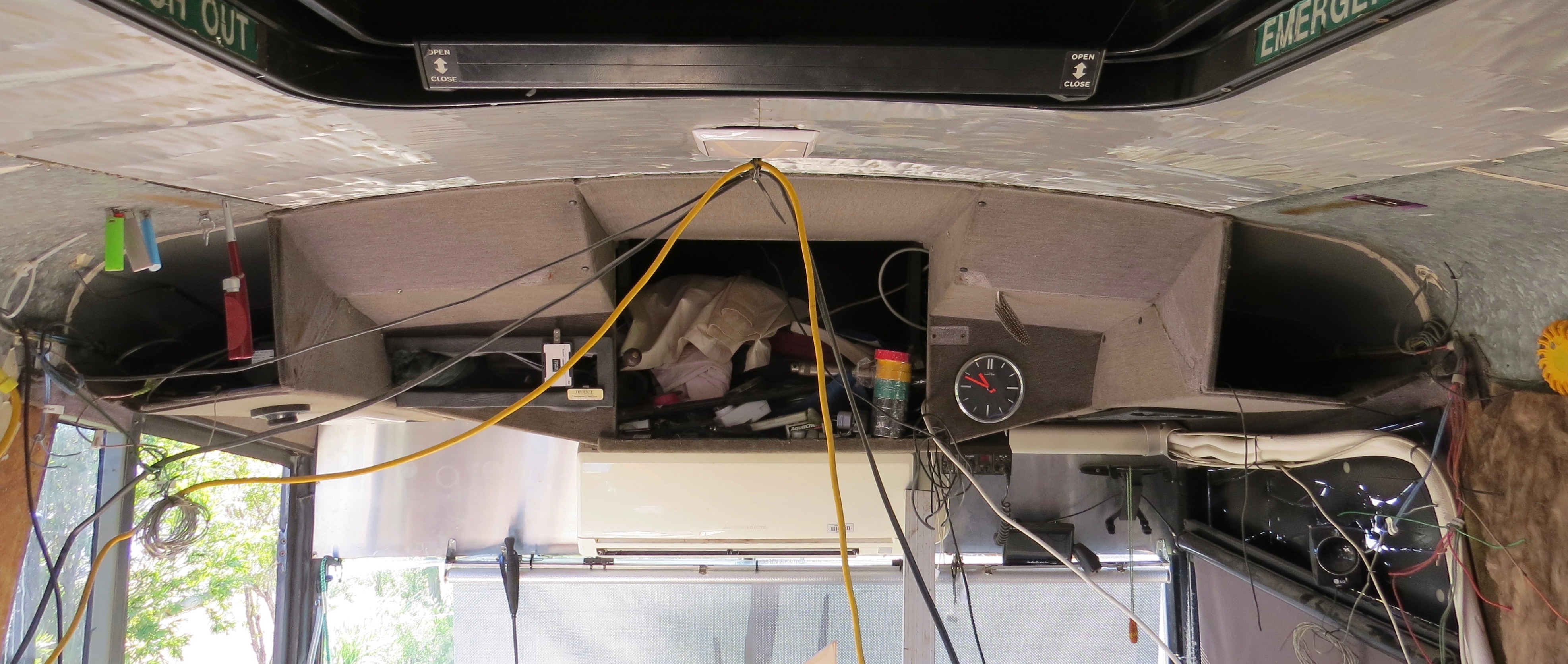

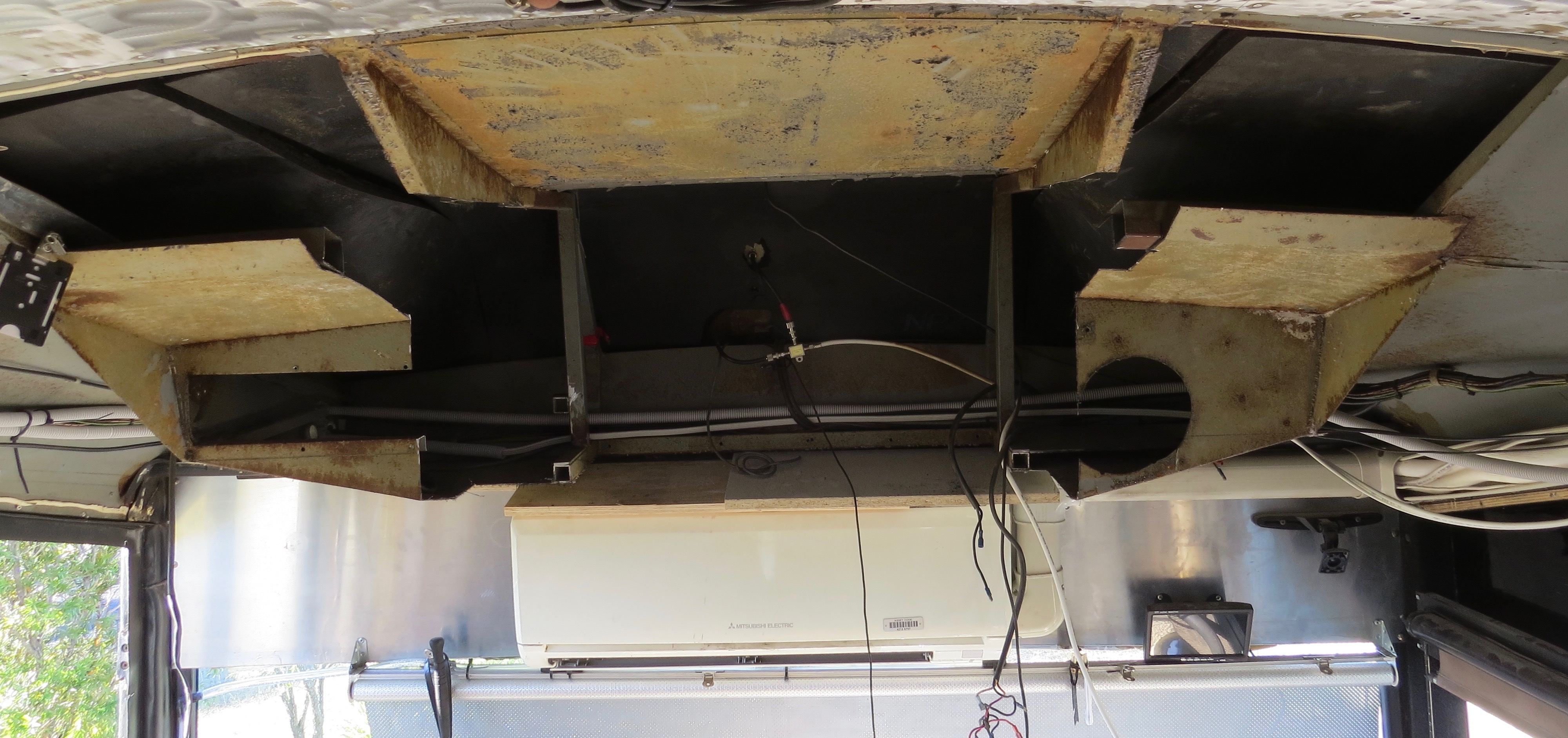

The last owner had put some sheet aluminium across the top of the front windscreen then fitted the Air-con there. This might have been ok then, but now things will have to change. I was going to make this one of the last jobs to do, but now it will have to be done before I can go any further .

To start with I will have to remove some of the old overhead T.V. cabinet to make room for the air-con. I must admit I do like pulling things apart, then trying to work out how I’m suppose to make it fit back together again.

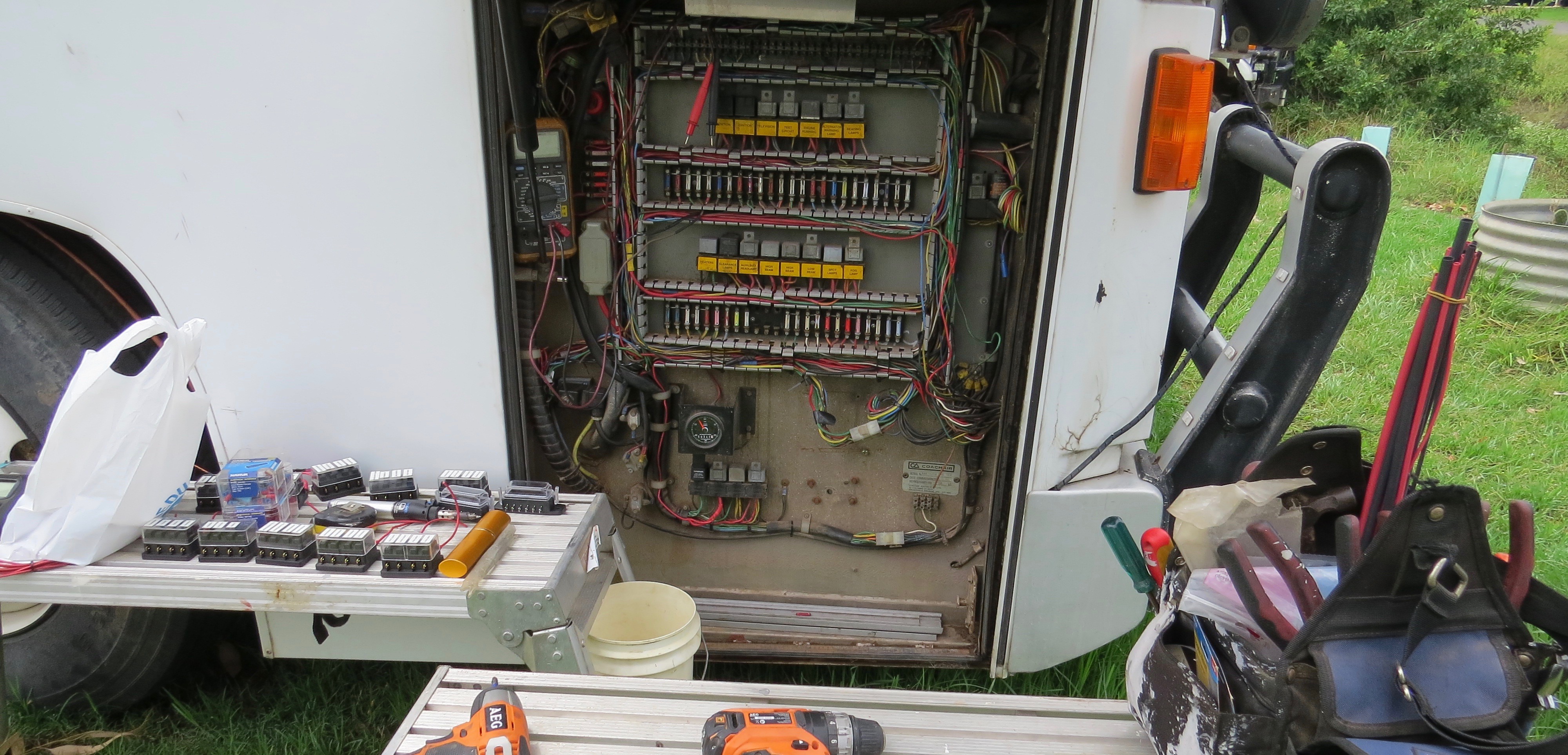

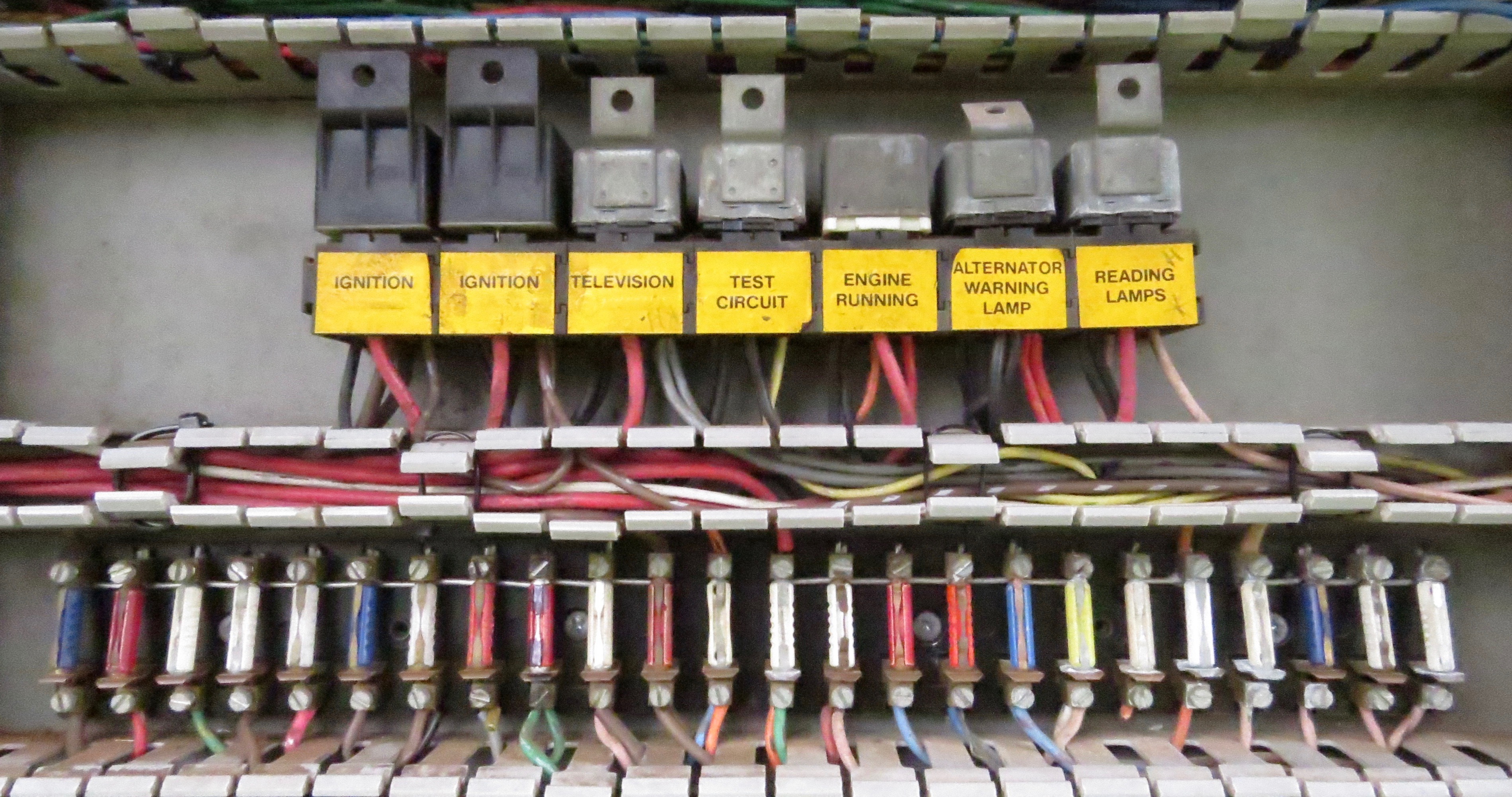

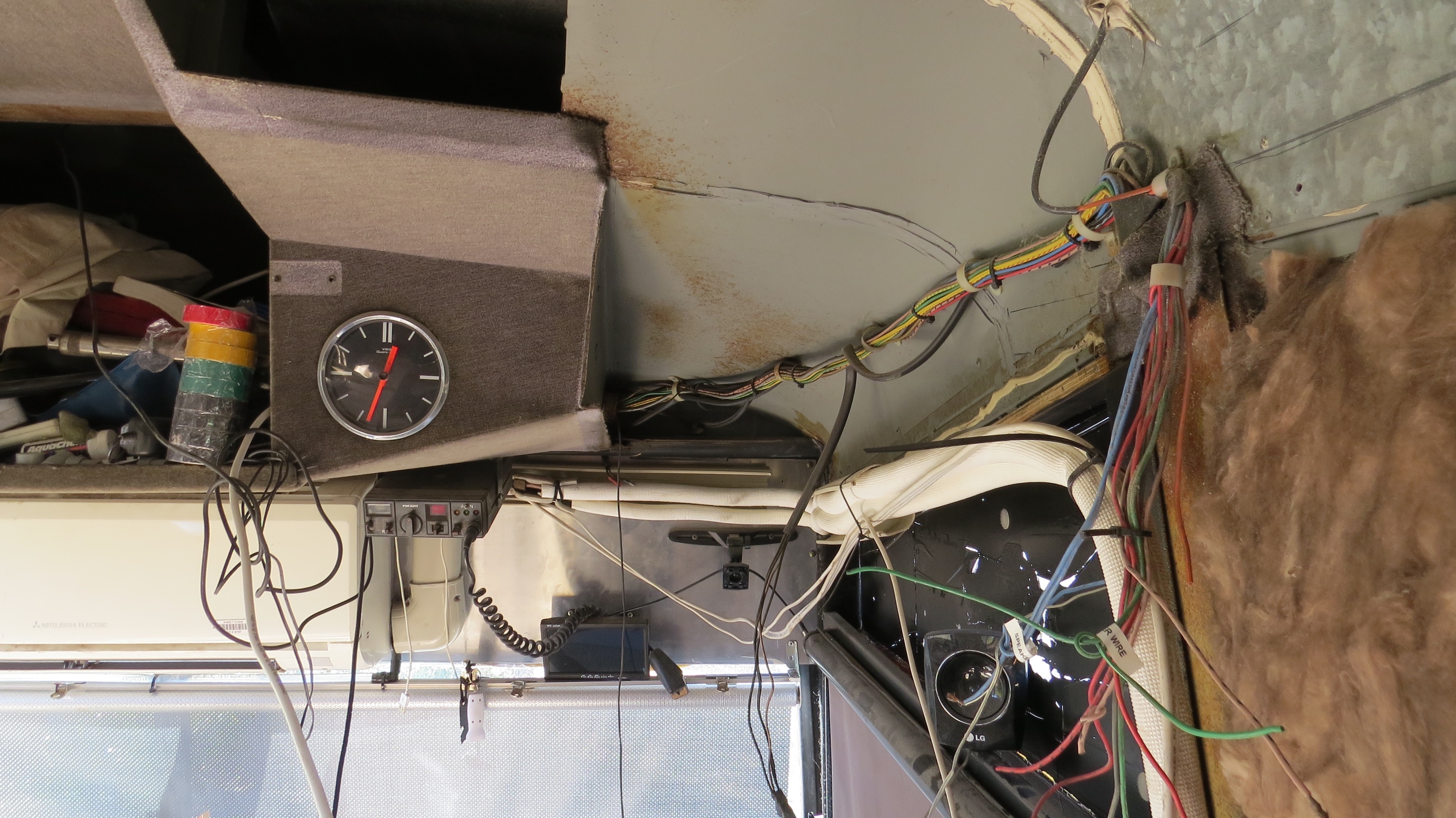

As you can see the air-con will not fit in the old T.V. hole, so I will have to make out where I have modify this section. before I go to far There is some 240v and 12v cables to run around behind where the air-con will go, I thought it might be a good time before I make it to hard for myself later on.

Now out with the grinder for lots of noise and dust, as it’s time to make a space for the air-con.

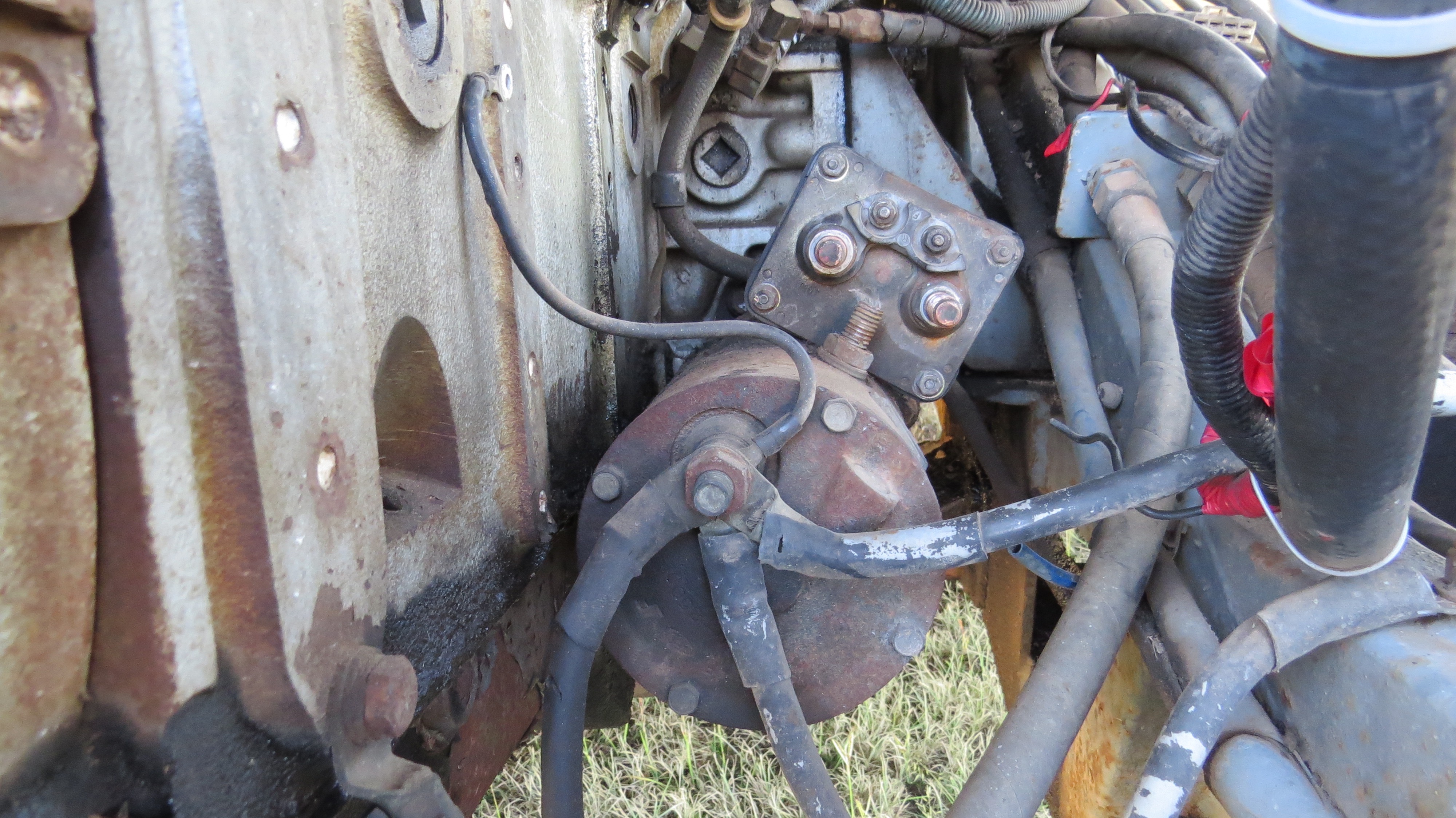

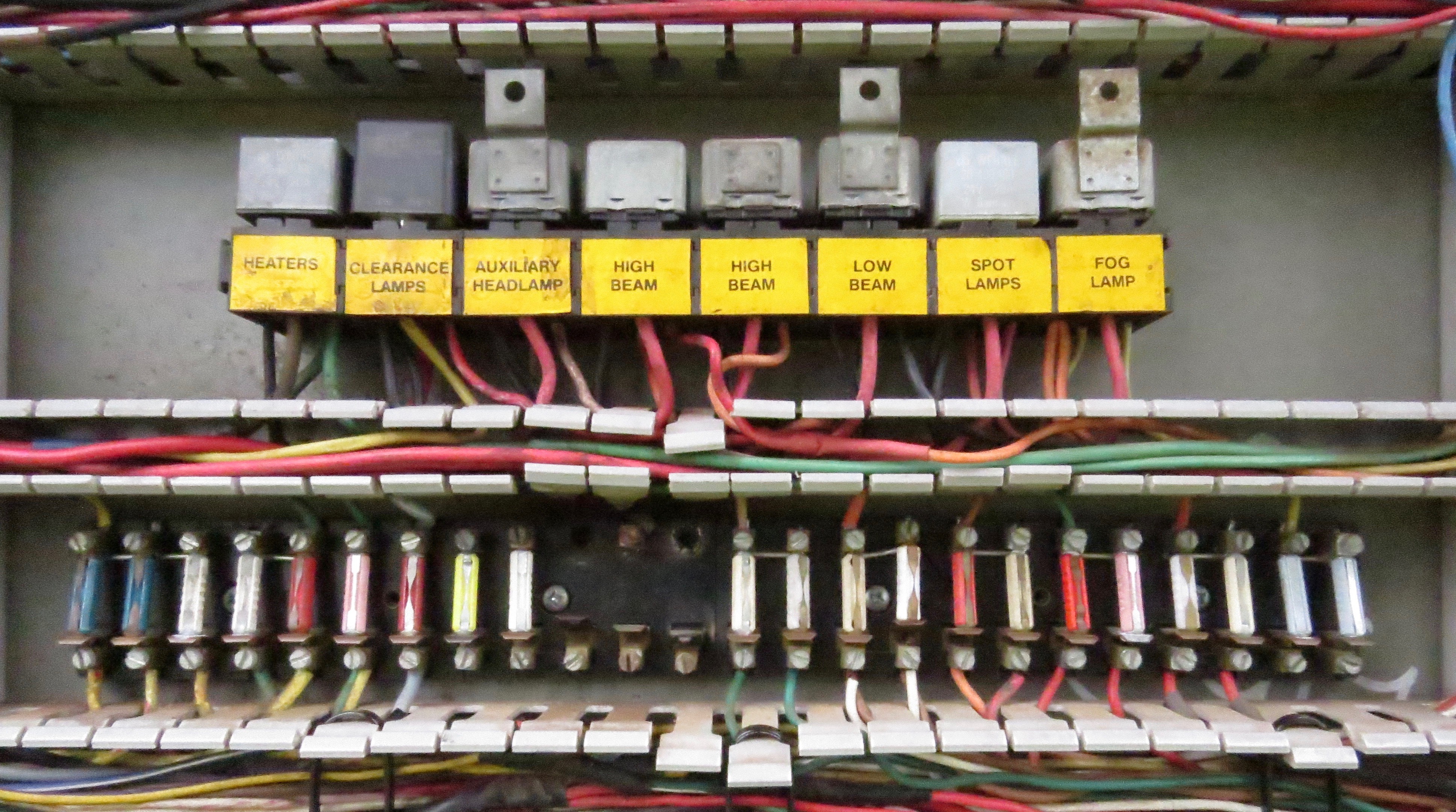

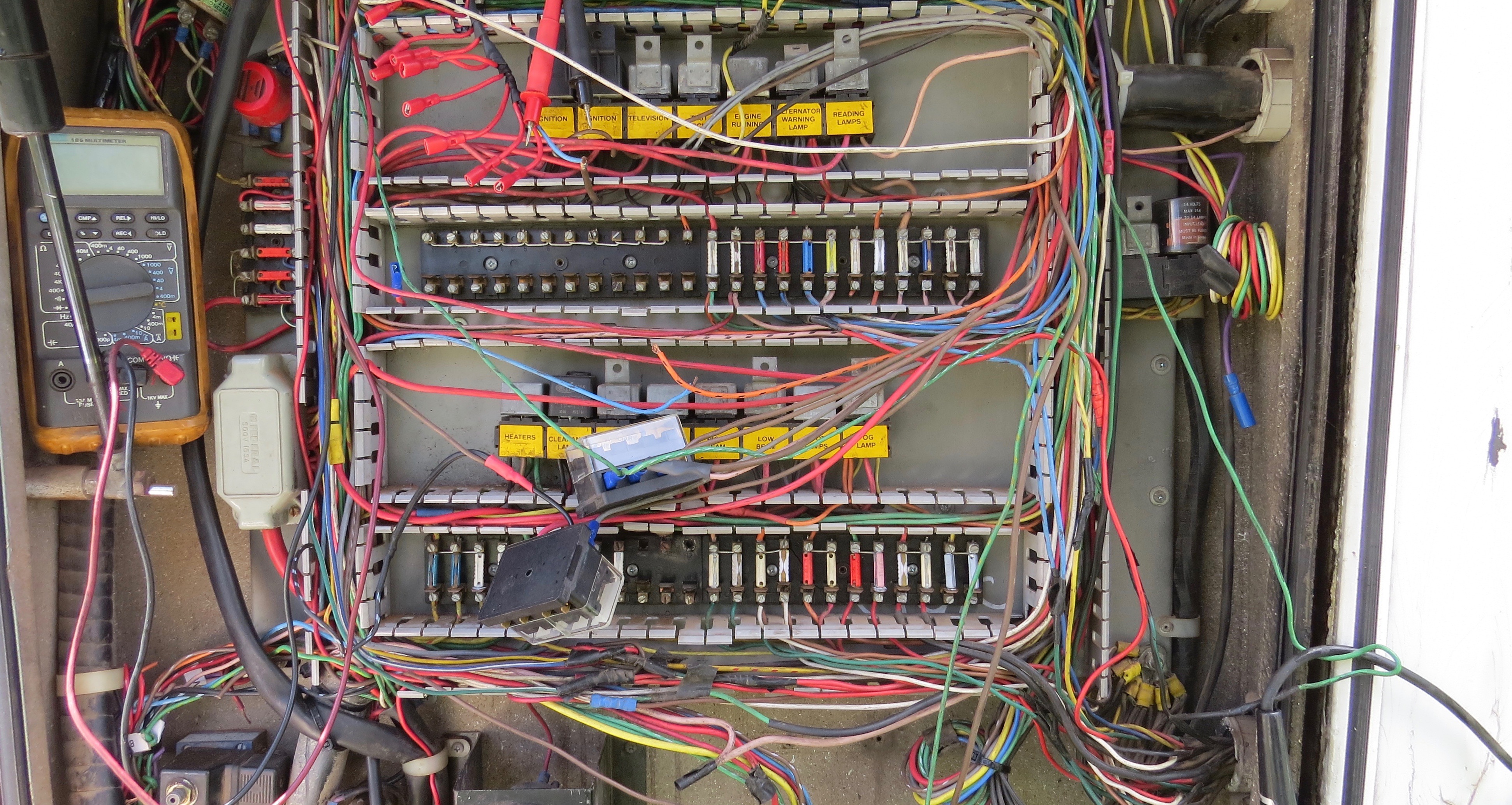

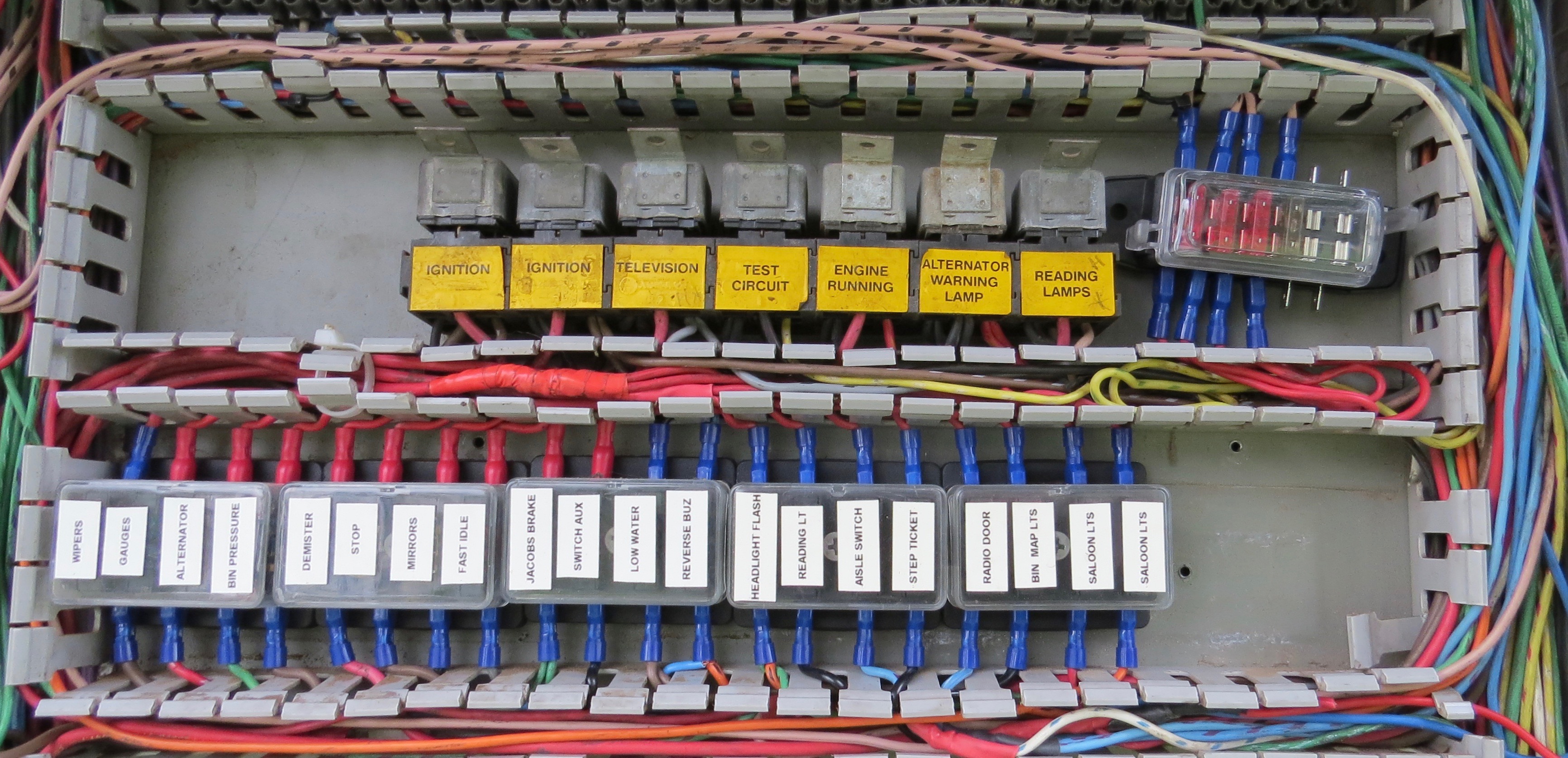

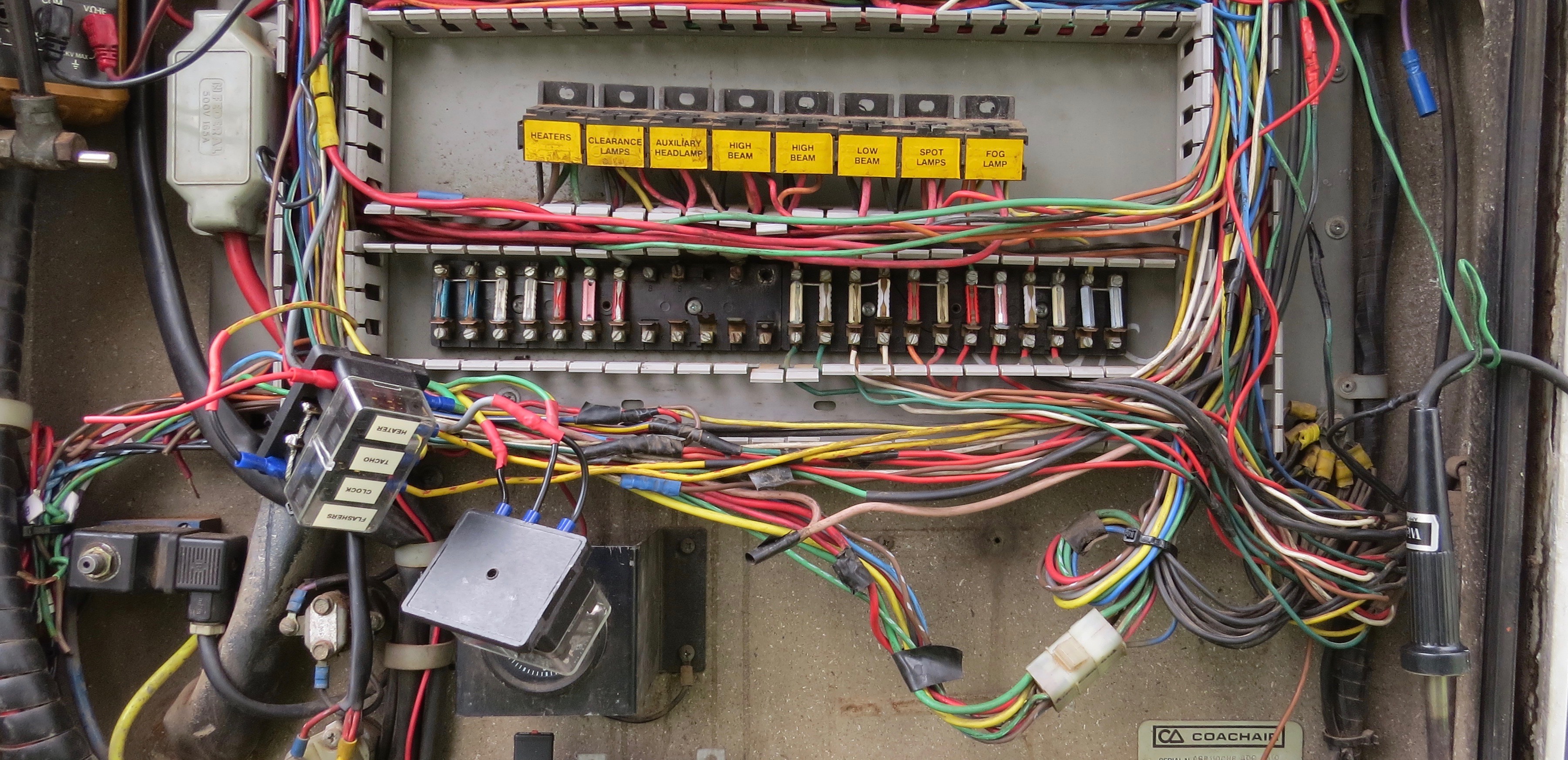

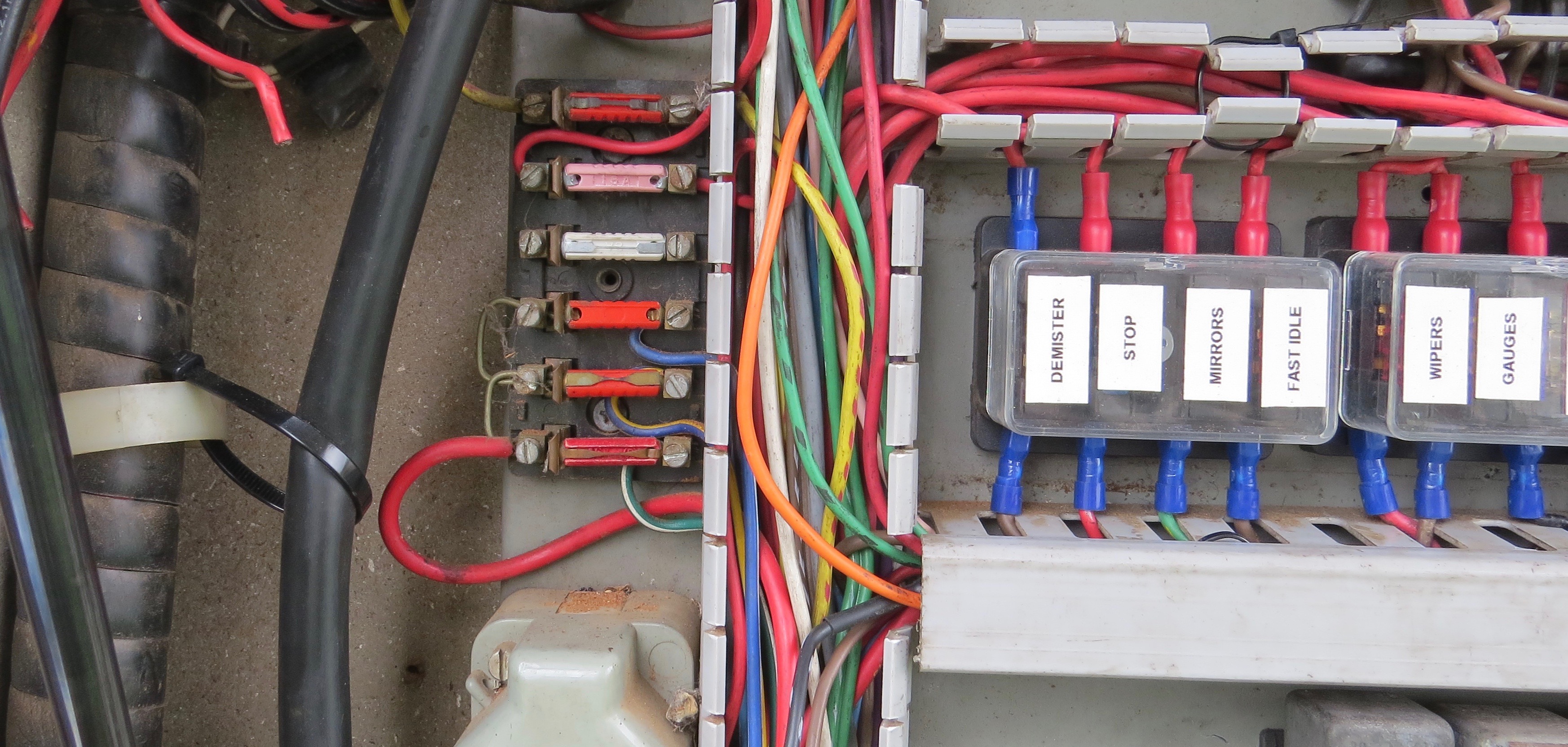

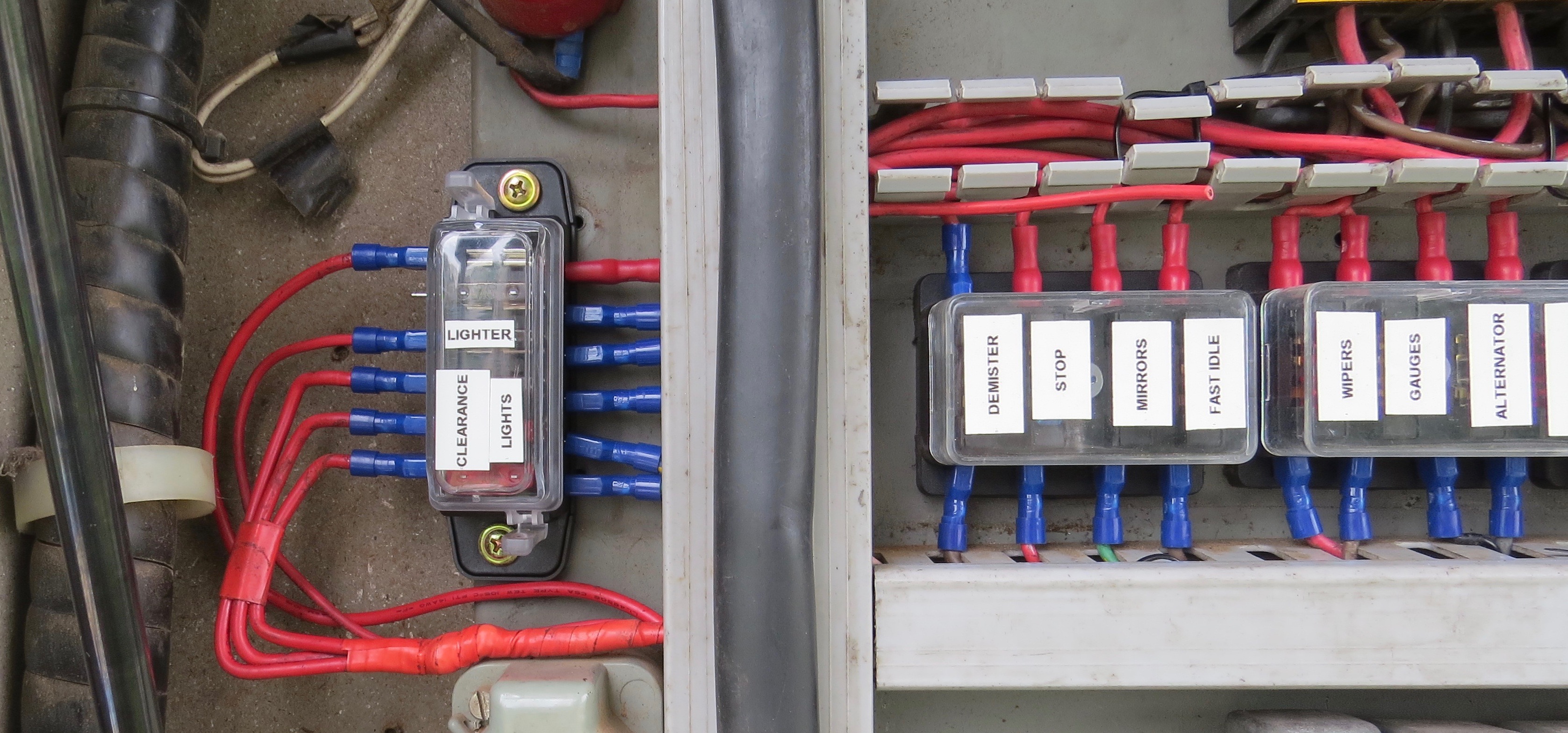

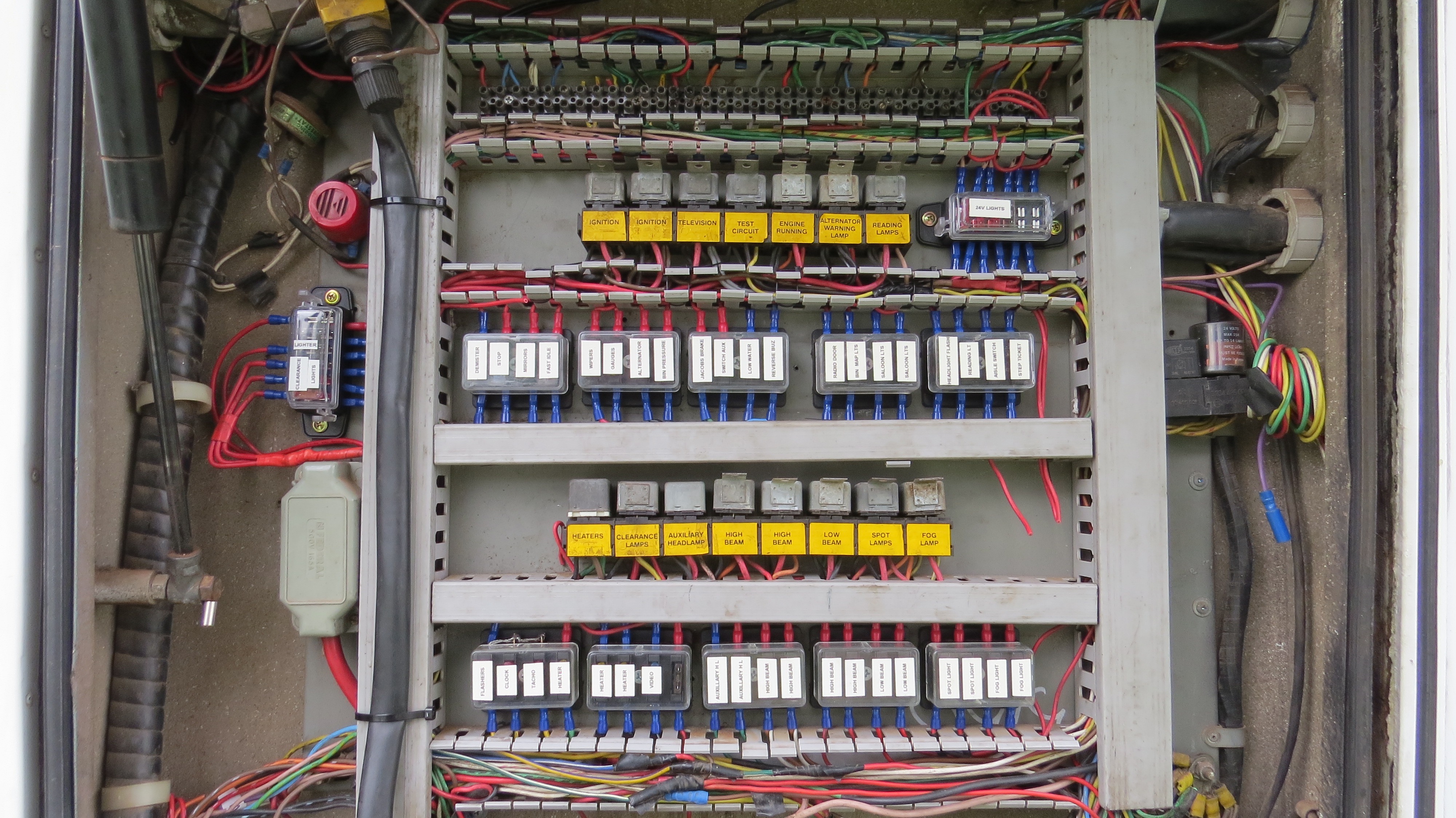

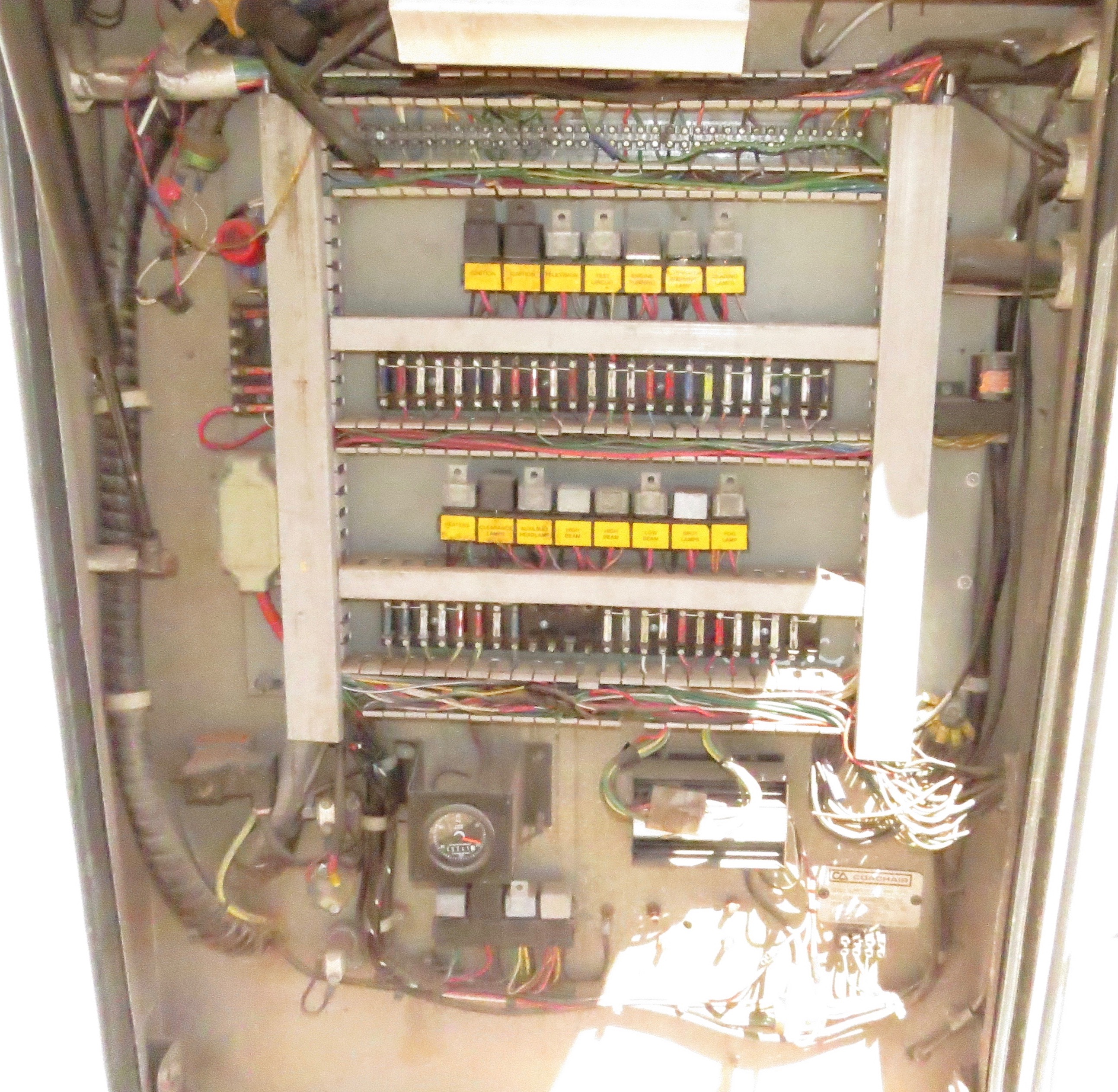

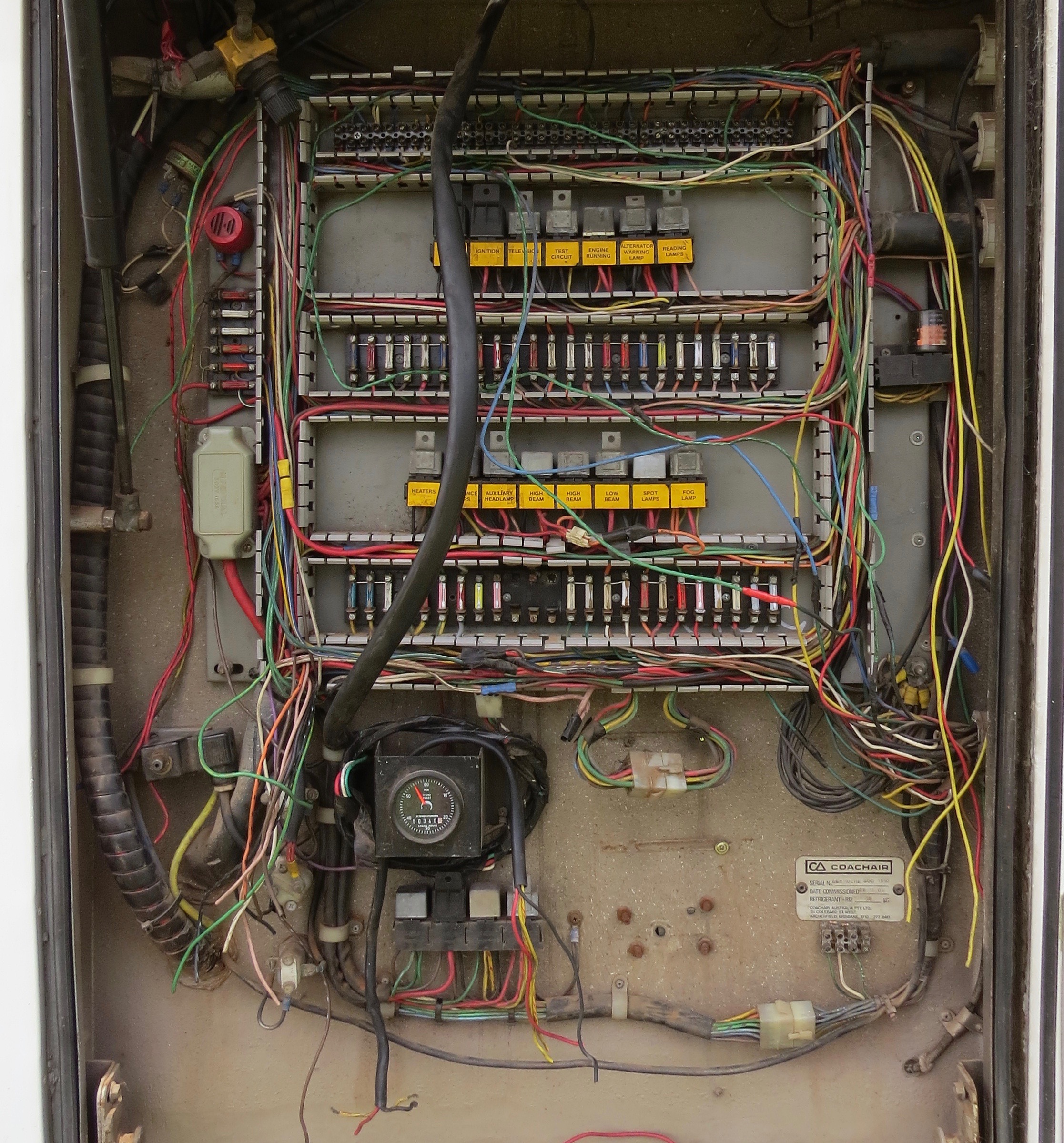

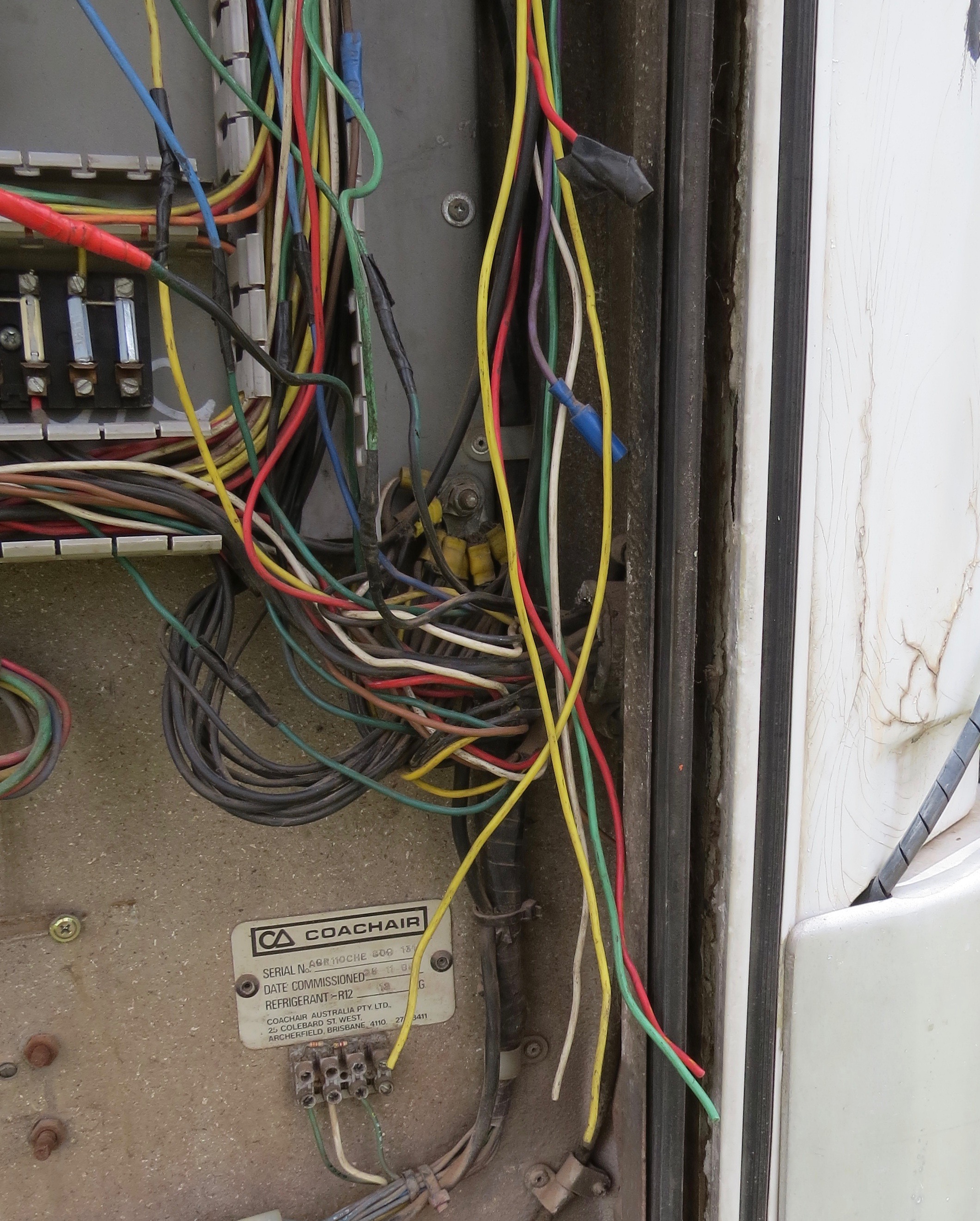

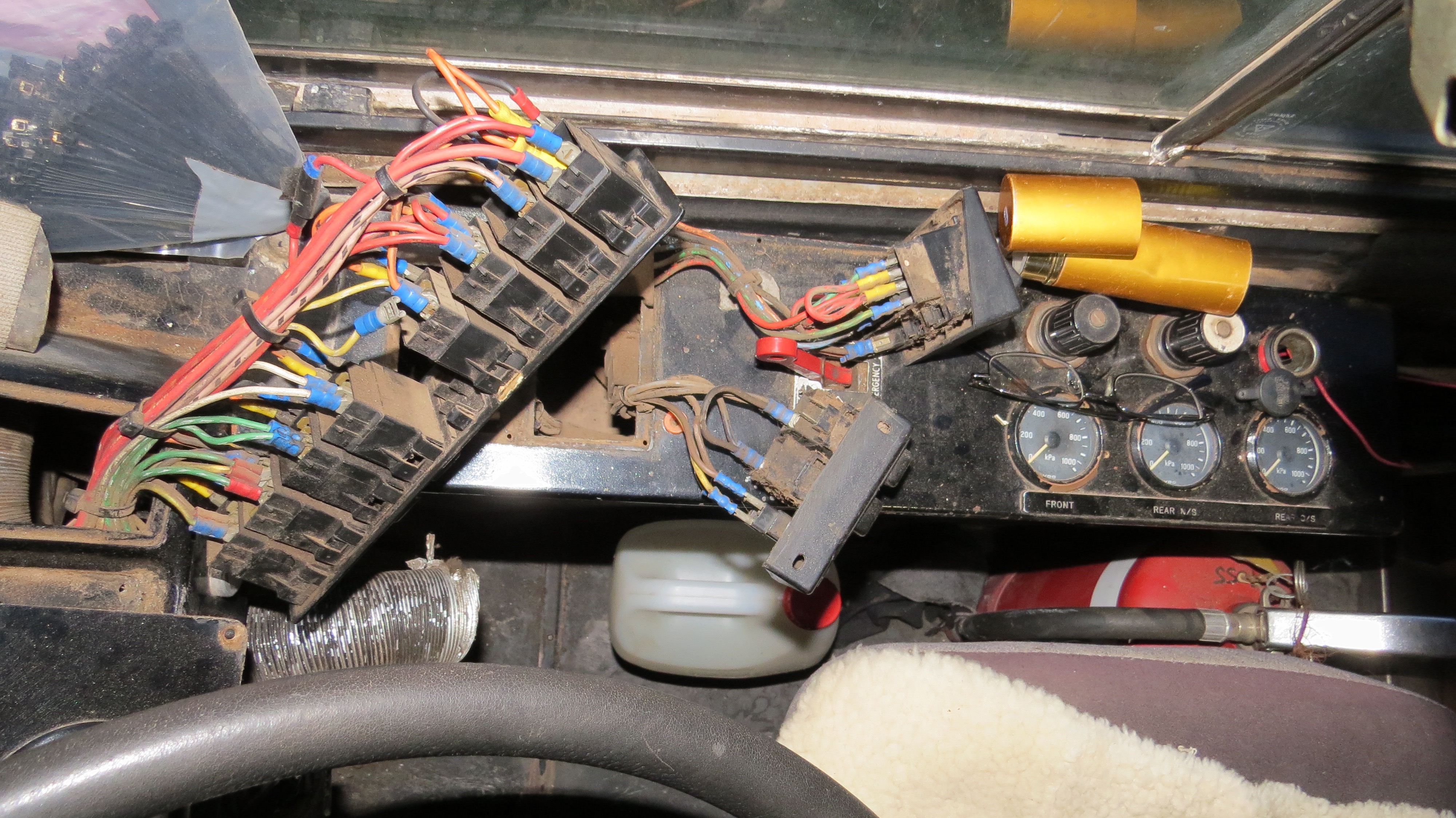

Now to start fixing this mess

As you can imagine nothing on the coach is square, so I can only cut and fit the ply one pice at a time. I can then work out where the next pice will go and what shape it will be. First of will be the backing board that will give me some thing to work from.

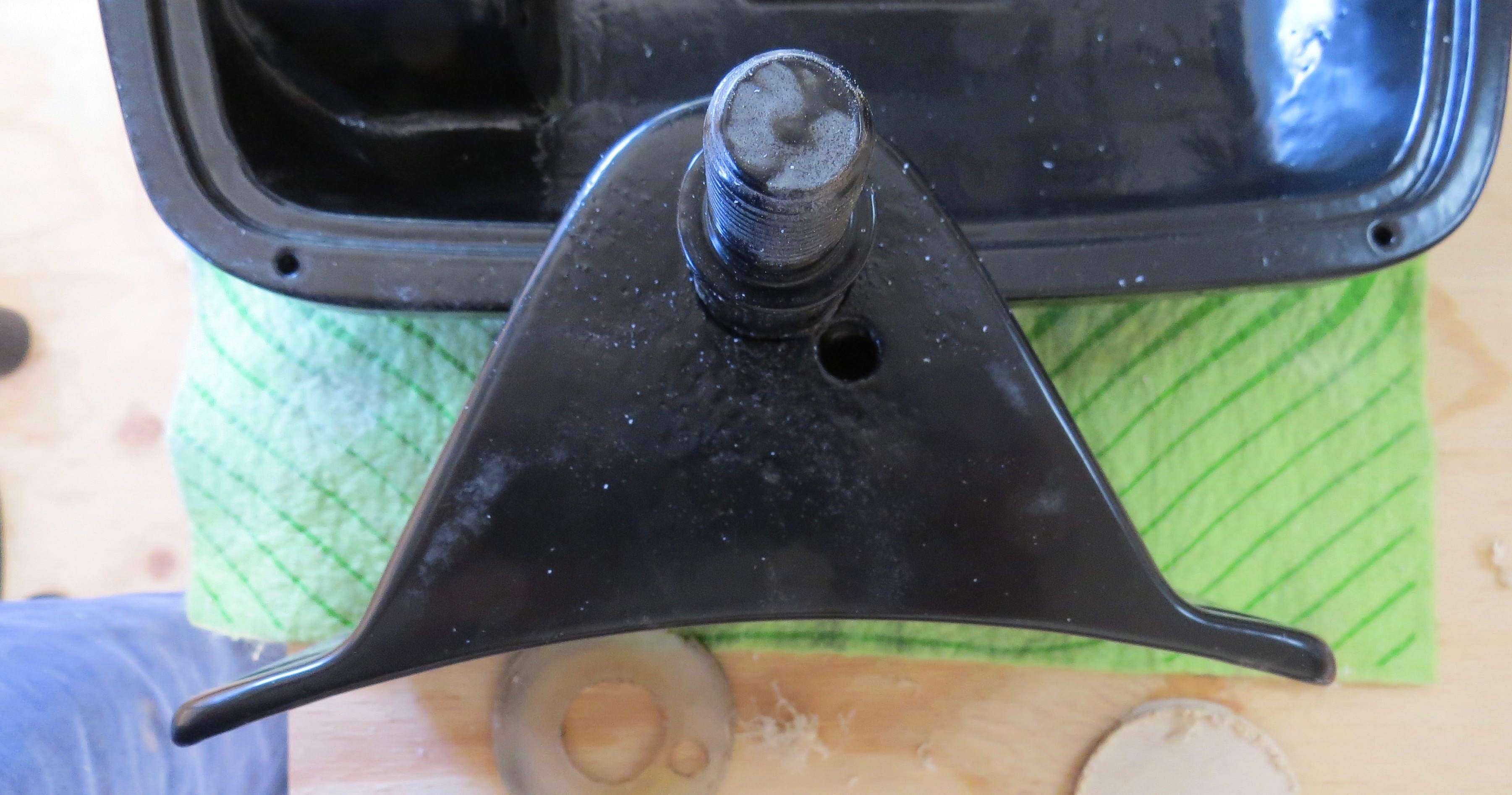

Let’s see if the air-con fit’s

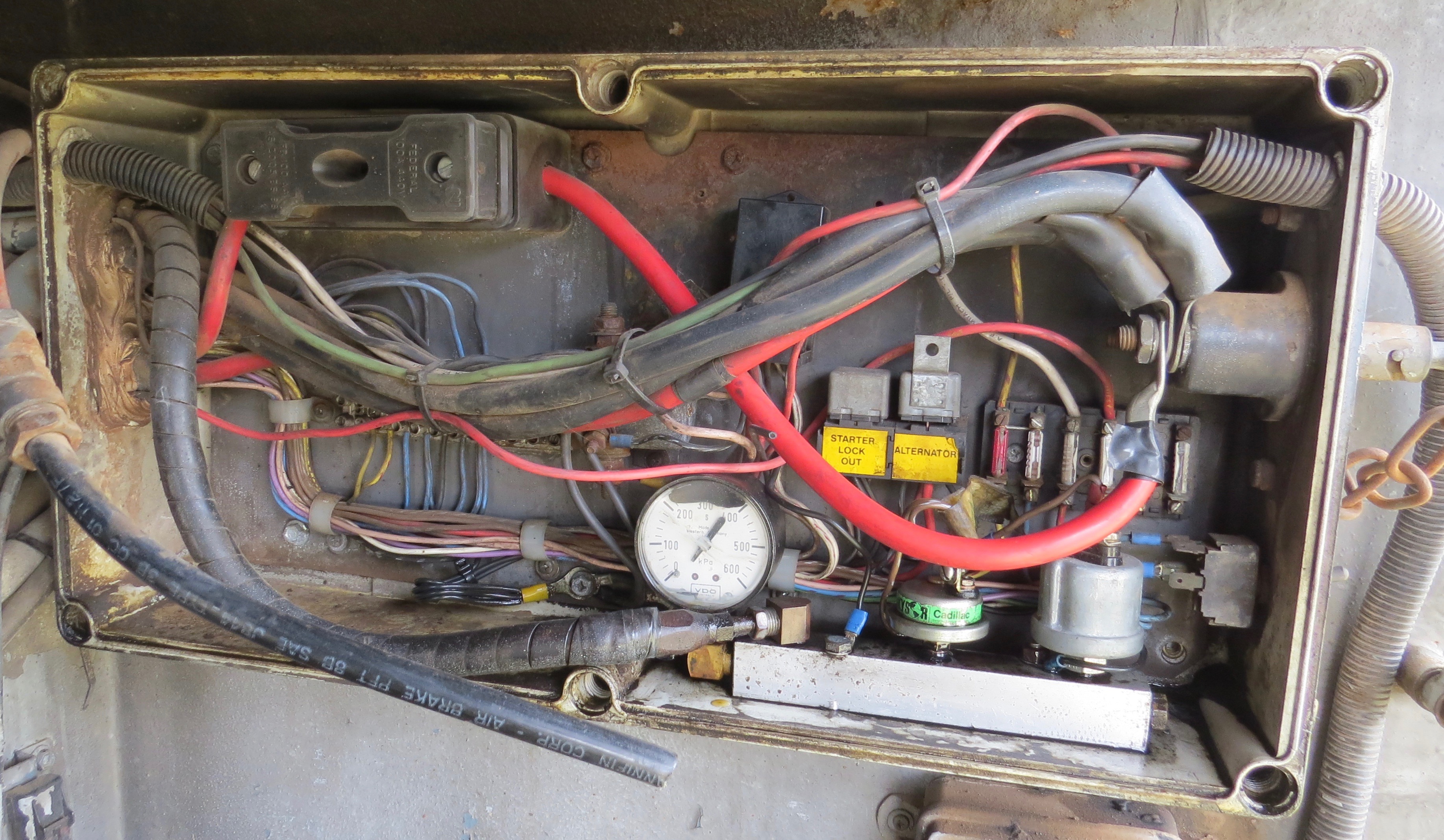

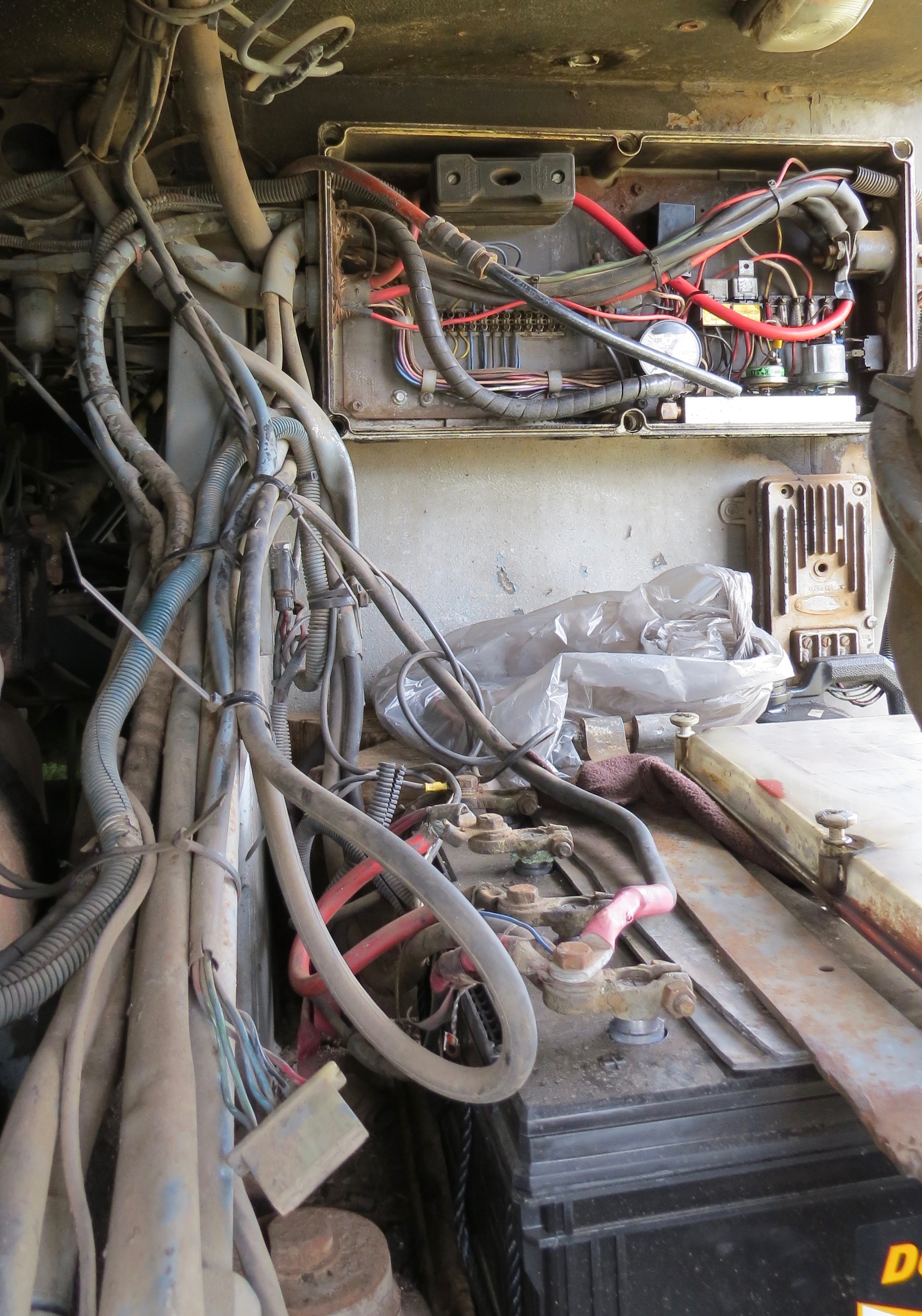

To start with pulling thing apart so that I don’t stuff things up. There is not much room to play with or put things apart from hopping the stuff does not break.

Well all I have to do now is some how by myself lift the air-con into place, holding the pipe work at the same time shape the pipes into their new area.

That’s all for this blog, more to come soon.